RAN

1½” E40-SX MODEL

DIAPHRAGM PUMP

OPERATING AND MAINTENANCE

MANUAL

MANUAL

CONTENTS

1.0. IMPORTANT SAFETY REQUIREMENTS

2.0. TECHNICAL DATA TABLE

3.0. DEFINITION OF DIAPHRAGM PUMP

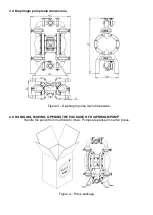

4.0. HANDLING, MOVING, OPENING PACKAGING OF DIAPHRAGM PUMP

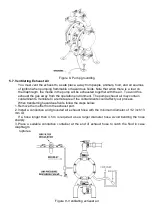

5.0. MOUNTING AND CONNECTING OF DIAPHRAGM PUMP

6.0. INSTRUCTIONS AND MANUAL OF DIAPHRAGM PUMP

7.0. ASSEMBLY AND DISMANTLING OF PARTS

8.0. PERIODIC MAINTENANCE

9.0. STORAGE OF DIAPHRAGM PUMP

10.0. PRECAUTIONS ON DISPOSING OF THE DIAPHRAGM PUMP

11.0. SERVICE POINTS

12.0. ORDERING SPARE PARTS

Attachment-1 Pump Performance Charts

Attachment-2 Gisan Warranty

Gisan Machinery Industry and Trade Co. Ltd.