Supplied By www.heating spares.co Tel. 0161 620 6677

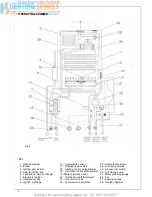

CONDENSING

FANNED FLUE BOILER

CSI SYSTEM

WITHOUT TIMER

NATURAL GAS (G20) (I

2H

) G.C.N

o

47 581 01 - CSI

LPG (G30-G31) (I

3+

) G.C.N

o

47 581 03 - CSI

Tested, certified and

service listed

Listed by The United Kingdom Water

Fitting Byelaws Scheme

WITH TIMER

NATURAL GAS (G 20) (I

2H

) G.C. N

O

47 581 02 - CSI

LPG (G 30 - G 31) (I

3+

) G.C.N

O

47 581 04 - CSI

INSTALLATION AND SERVICING INSTRUCTIONS

TO BE LEFT WITH USER

Technical and illustrative data are not binding and can be modified without prior notice.

The descriptions and illustrations in the present booklet are for guideline purposes only.

RAVENHEAT MANUFACTURING LTD., CHARTISTS WAY, MORLEY, LEEDS, LS27 9ET. -TELEPHONE (0113) 252 7007

Summary of Contents for CSI System

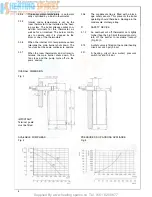

Page 16: ...Supplied By www heating spares co Tel 0161 620 6677...

Page 26: ...Supplied By www heating spares co Tel 0161 620 6677 2 6...

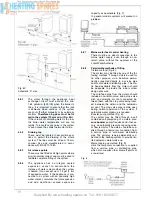

Page 41: ...Supplied By www heating spares co Tel 0161 620 6677 Fig 90 Fig 91 Fig 93 41...

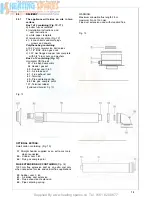

Page 45: ...Supplied By www heating spares co Tel 0161 620 6677...

Page 49: ...Supplied By www heating spares co Tel 0161 620 6677...