Hydraulic Pump

Installation Guide

Drives covered:

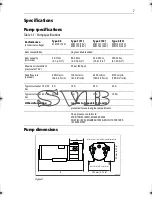

E12139

Type 0.5 Hydraulic Pump 12 V

M81120

Type 1 Hydraulic Pump 12 V

M81119

Type 1 Hydraulic Pump 24 V

M81121

Type 2 Hydraulic Pump 12 V

M81123

Type 2 Hydraulic Pump 24 V

M81122

Type 3 Hydraulic Pump 12 V

M81124

Type 3 Hydraulic Pump 24 V

Document number: 81178-5

April 2013

81178_5.book Page 1 Wednesday, April 24, 2013 6:42 PM

Summary of Contents for E12139

Page 24: ......