DO NOT OPEN RELOAD KIT UNTIL READY TO USE.

PARTS:

RMS™-75 HARDWARE

75mm aft closure

1

75/5120 case

1

75mm plugged forward closure

1

75mm forward seal disk

1

RELOAD PARTS KIT

Nozzle (large black plastic part)

1

Liner (2-3/4" O.D. black plastic tube)

1

Propellant grains (7/8” core)

4

Fwd & aft o-rings (1/8" thick X 2-3/4" O.D.)

2

Forward seal disk o-ring (3/32” thick x 2-9/16” O.D.)

1

Smoke charge (short solid part)

1

Smoke charge insulator (1-1/2" O.D. tube)

1

Nozzle Cap (2-1/4” dia. red cap)

1

ITEMS NEEDED FOR USE:

• Synco™ Super Lube™ or other grease

• Hobby knife

• Electric match w/thermalite, Firestar™ or other igniter

• Masking tape

• Wet wipes or damp paper towels

SAVE THE RELOAD KIT PLASTIC BAG FOR THE USED RE-

LOAD PARTS. DISPOSE OF BAG AND PARTS PROPERLY.

HIGH-POWER RMS™

HIGH-POWER RMS™

HIGH-POWER RMS™

HIGH-POWER RMS™

HIGH-POWER RMS™

Assembly and Operation Instructions

Assembly and Operation Instructions

READ THIS BEFORE YOU BEGIN:

• Study the illustrations and sequence of assembly.

THE SEQUENCE OF ASSEMBLY IS

EXTREMELY IMPORTANT. READ ALL INSTRUCTIONS BEFORE USE. USE RMS™

MOTORS AND RELOAD KITS ONLY IN ACCORDANCE WITH ALL INSTRUCTIONS.

Review the parts list and become familiar with all parts before assembly.

IF ANY PARTS

ARE MISSING OR DAMAGED, CONTACT RCS AT 1-435-865-7100 or email at

warranty@aerotech-rocketry.com.

•

DO NOT USE ANY PARTS OF THE RMS™ SYSTEM THAT ARE DAMAGED IN ANY

WAY.

If in doubt, contact RCS at the number above for assistance.

•

DO NOT MODIFY THE MOTOR IN ANY WAY.

Modification of the motor or the reload

kit parts could result in motor failure, lead to the destruction of both your rocket and motor

and may cause personal injury, death and/or property damage. Modification of the motor

or reload kit in any way will invalidate your motor warranty.

•

USE ONLY AEROTECH/RCS RMS™ RELOAD KITS AND MOTOR PARTS TO

REFURBISH YOUR RMS™ MOTOR.

The AeroTech/RCS reload kits have been

designed specifically for use in your particular AeroTech/RCS RMS™ motor. Use of

imitation components may destroy your motor, rocket and payload and will invalidate

your motor warranty. Only use AeroTech/RCS RMS™ reload kits intended for your

specific AeroTech/RCS RMS™ motor.

DO NOT INTERCHANGE PARTS!

Do not use

AeroTech/RCS RMS™ reload kits or motor components for any other purpose than to

refurbish an AeroTech/RCS RMS™ motor.

•

DO NOT REUSE ANY OF THE DISPOSABLE PARTS OF THE RMS™ RELOAD KIT.

This includes the liner, nozzle and o-rings. These components have been designed for

one use only and must be discarded after firing. Reuse can result in motor failure during

subsequent operation and will invalidate your motor warranty.

• Motors are hot after firing. Although the RMS™ operates at a lower temperature than

most disposable motors, the higher thermal conductivity of the aluminum motor parts

may make it seem otherwise. If necessary to handle a motor before it has cooled down,

use a rag or similar article.

• Read and follow the safety code of the Tripoli Rocketry Association (TRA) and comply

with all federal, state and local laws in all activities involving high power rockets.

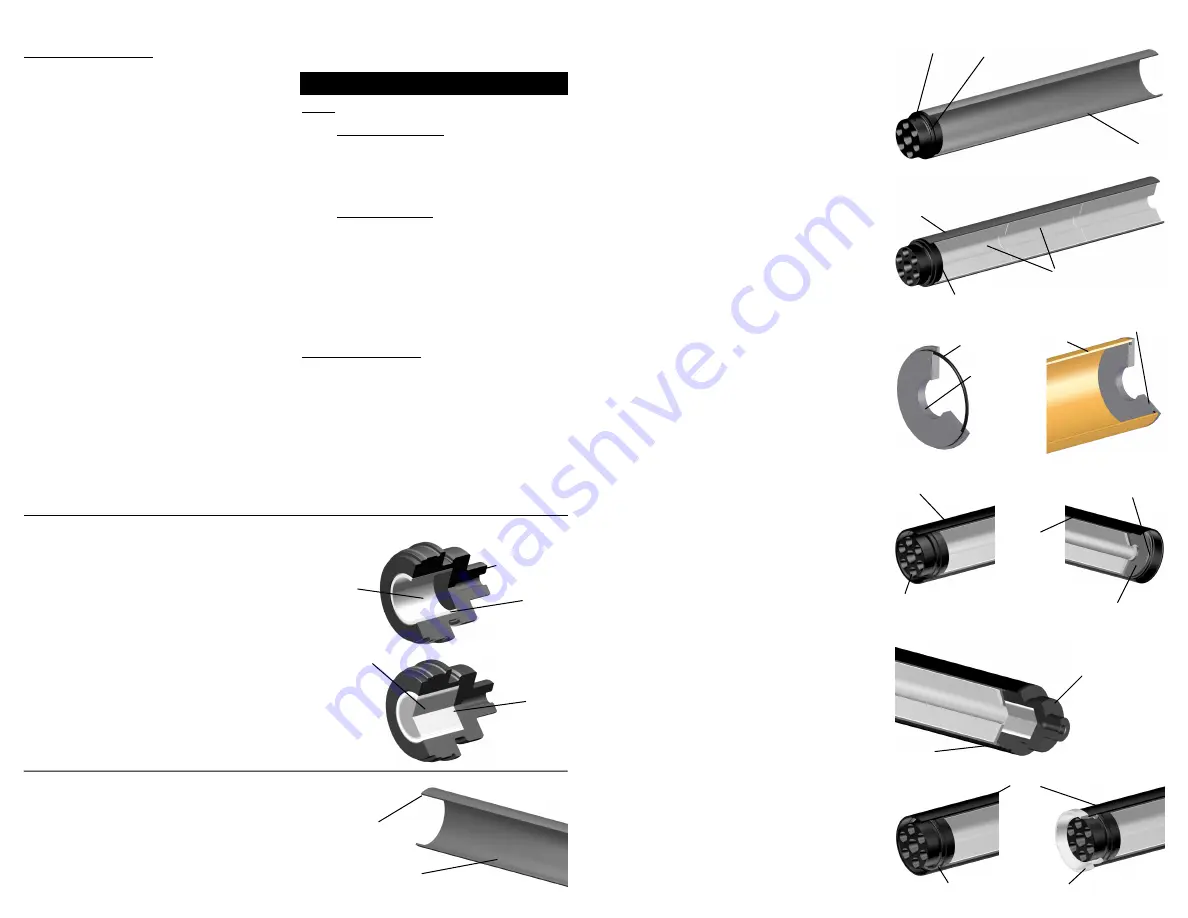

Chapter 1. Forward Closure Assembly

1-1.

Apply a light coat of Synco™ Super Lube™ or other

grease to all threads and all three o-rings. This will

facilitate assembly and prevents the threads from seiz-

ing.

1-2.

Fig.-1:

Hold the forward (black) closure in a vertical

position, smoke charge cavity facing up. Insert the

smoke charge insulator into the smoke charge cavity

until it is seated against the forward end of the cavity.

1-3.

Fig.-2:

Apply a liberal amount of grease to one end of

the smoke charge element. Insert the

greased

end of

the smoke charge element into the smoke charge cavity

until it is seated against the end of the cavity. Set the

completed forward closure assembly aside.

2-1.

Fig.-3:

Using a hobby knife or similar tool, carefully

deburr (chamfer) both inside edges of the liner tube (2-

3/4” O.D. black plastic tube).

75mm Forward

(Black) Closure

Smoke Charge

Insulator

Smoke

Charge

Cavity

Smoke Charge

Element

Fig.-1

Fig.-2

2-2.

Fig.-4:

Insert the larger diameter portion of the nozzle

into one end of the liner, with the nozzle liner flange

seated against the liner.

NOTE:

RMS-75/5120 motors

use a single large throat nozzle rather than the multiple-

throat “Medusa” nozzle shown in the illustrations.

2-3.

Fig.-5:

Perform the remaining assembly steps with the

liner held in a horizontal position. Install the propellant

grains into the liner, seated against the nozzle grain

flange.

NOTE:

Three propellant grains are shown in all

illustrations for simplicity. RMS-75/5120 motors use

four (4) grains.

2-4.

Fig.-6:

Place the greased forward seal disk (3/32" thick

X 2-9/16" O.D.) o-ring into the groove in the forward seal

disk.

2-5.

Fig.-7:

Insert the smaller (o-ring) end of the seal disk

into the open end of the liner tube until the seal disk

flange is seated against the end of the liner.

2-6.

Fig.-8:

Push the liner assembly into the motor case until

the nozzle protrudes approximately 1-3/4” from the end

of the case.

NOTE:

A coating of grease on the outside

surface of the liner will facilitate installation and casing

cleanup after motor firing.

2-6.

Fig.-9:

Place the greased forward (1/8" thick X 2-3/4"

O.D.) o-ring into the forward (bulkhead) end of the case

until it is seated against the forward seal disk.

2-7.

Fig.-10:

Thread the previously-completed forward clo-

sure assembly into the forward end of the motor case by

hand until it is seated against the case.

NOTE:

There

will be considerable resistance to threading in the

closure during the last 1/8" to 3/16" of travel.

2-8.

Fig.-11:

Place the greased aft (1/8" thick X 2-3/4" O.D.)

o-ring into the groove in the nozzle.

2-9.

Fig.-12:

Thread the aft closure into the aft end of the

motor case by hand until it is seated against the case.

NOTE:

There will be considerable resistance to thread-

ing in the closure during the last 1/8" to 3/16" of travel.

It is normal if a slight (1/32” to 1/16”) gap remains

between the closure and the case, and the grains rattle

slightly in the liner after tightening.

Fig.-6

Case

Fig.-8

Fig.-9

Forward O-Ring

Fig.-3

Fig.-12

Aft Closure

Case

Fig.-11

Fig.-10

Forward Closure

Assembly

Aft

(Nozzle)

End Views

Case

Nozzle

Case

Fig.-4

Fig.-5

Chapter 2. Case Assembly

Deburr (Chamfer)

Both inner Edges

Liner

Greased

End of

Smoke Charge

Chapter 2. Case Assembly (Cont’d)

Liner

(Deburred)

Nozzle (Protrudes

About 1-3/4”)

Aft O-ring

Nozzle

Liner Flange

Forward Seal

Disk (Aluminum

Washer)

Greased Forward

Seal Disk O-ring

Fig.-7

Forward Seal

Disk Assembly

Liner

Forward

Seal Disk

Liner

Nozzle

Grain Flange

Propellant

Grains (7/8” Core)