SAFETY

Personal injury and/or equipment damage may result if proper

safety precautions are not observed.

• Ensure that reel is properly installed before connecting input and

output hoses.

• Bleed fluid/gas pressure from system before servicing reel.

• Before connecting reel to supply line, ensure that pressure does

not exceed maximum working pressure rating of reel.

• Remember, even low pressure is very dangerous and can cause

personal injury or death.

• Be aware of machinery and personnel in work area.

• If a leak occurs in the hose or reel, remove system pressure

immediately.

• A high tension spring assembly is contained within the reel.

Exercise extreme caution.

• Pull hose from reel by grasping the hose itself, not the control

valve.

• If reel ceases to unwind or rewind, remove system pressure

immediately. Do not pull or jerk on hose!

• Treat and respect the hose reel as any other piece of machinery,

observing all common safety practices.

Operating Instructions

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Form# 964-998 Rev: 8/2018

Read this manual carefully before installing, operating or

servicing this equipment.

IMPORTANT

Dimensions

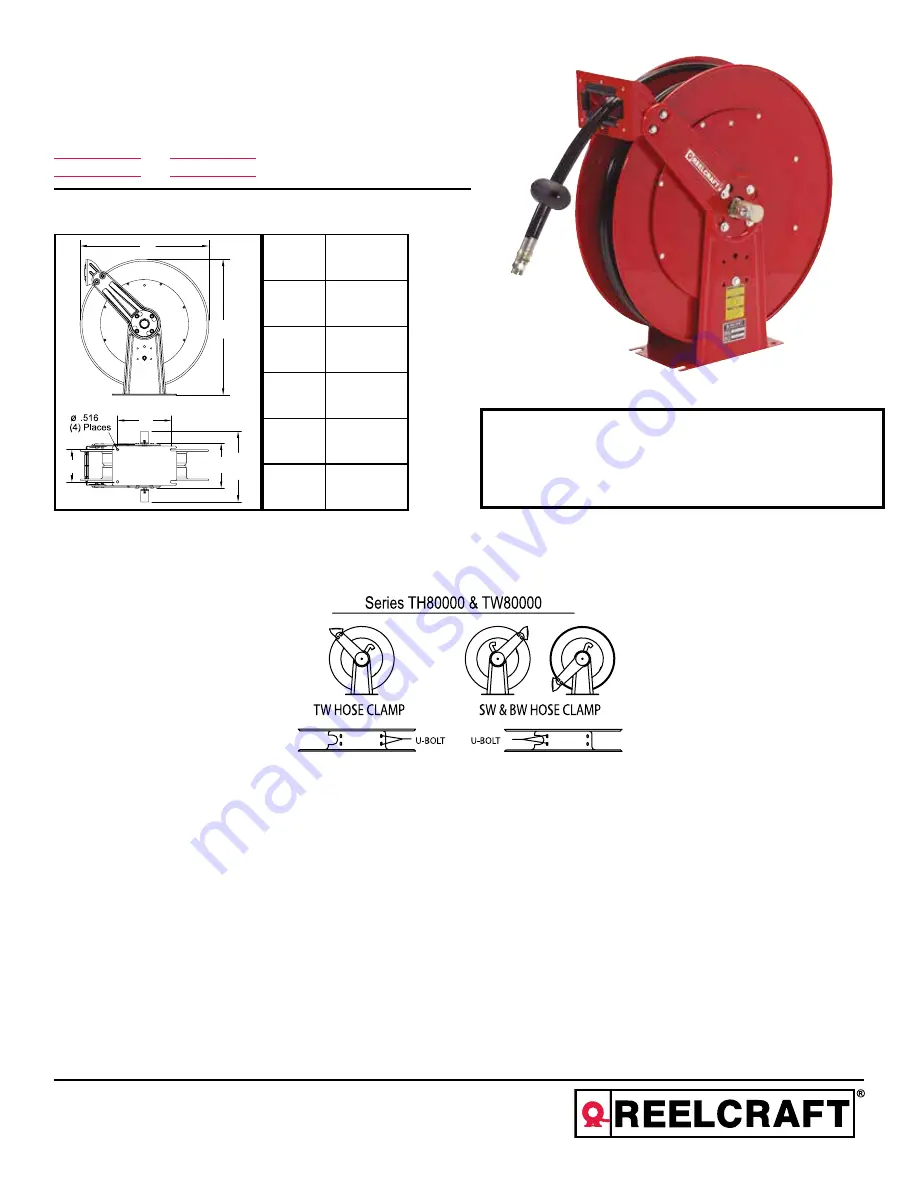

Series TH80000 Spring Driven Hose Reels

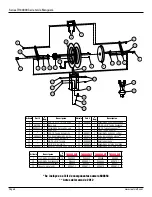

Figure A

TH86050 OMP

TH86000 OMP

TH88050 OMP

TH88000 OMP

A

25 3/8”

B

24”

C

10”

D

6”

E

12 7/8”

F

8 1/8”

A

B

C

D

E

F