FPI FIREPLACE PRODUCTS INTERNATIONAL LTD. 6988 Venture St., Delta, BC Canada, V4G 1H4

919-914

MODELS: U39-NG11 Natural Gas U39-LP11 Propane

04.24.19

Ultimate™ U39 Freestanding Gas Stove

Owners &

Installation Manual

www.regency-fire.com

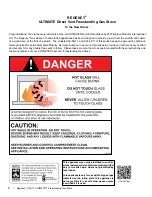

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

- WHAT TO DO IF YOU SMELL GAS

•

Do not try to light any appliance.

• Do not touch any electrical switch: do not use any phone in your building.

Leave the building immediately.

• Immediately call your gas supplier from a neighbour's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious

injury, death, or property damage.

Installer

: Please complete the details on the back cover

and leave this manual with the homeowner.

Homeowner:

Please keep these instructions for future reference.

Tested by:

Certified to/Certifié pour: CSA 2.17-2017

ANSI Z21.88-2017

CSA 2.33-2017

Summary of Contents for U39-LP11

Page 49: ...Regency U39 11 ULTIMATE Freestanding Gas Stove 49 notes ...

Page 54: ......

Page 55: ......