Summary of Contents for BARRACUDA 200ZW

Page 1: ...INSTRUCTION MANUAL BARRACUDA 200ZW PORTABLE WALKING FOOT SEWING MACHINE ...

Page 2: ......

Page 8: ...WINDING THE BOBBIN 3 4 2 5 1 03 ...

Page 9: ...THREADING THE MACHINE AND NEEDLE 3 6 4 5 2 1 7 8 6 5 04 ...

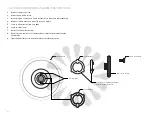

Page 12: ...ADJUSTING THE NEEDLE THREAD TENSION ADJUSTING THE bobbin TENSION 07 ...

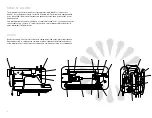

Page 15: ...CONSTRUCTIONAL 10 ...

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......