REVO - LOW PROFILE 35 DRILL

ORIGINAL INSTRUCTIONS

G&J Hall Ltd, Burgess Road, Sheffield, S9 3WD, England

Tel: +44 114 254 3206 Fax: +44 114 244 9256

Email: info@gjhall.co.uk Web: www.revo-tools.co.uk

www.revo-tools.co.uk

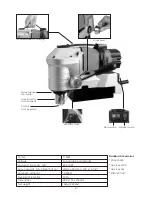

Machine shown

REVO Low Profile 35

WARNING !

When using electric power tools

basic safety precautions should

always be used to reduce the risk

of fire, electric shock and personal

injury.

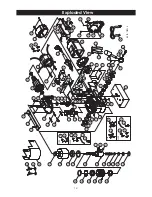

Summary of Contents for Low Profile 35

Page 11: ...11 Wiring ...