06-199

MAY 19

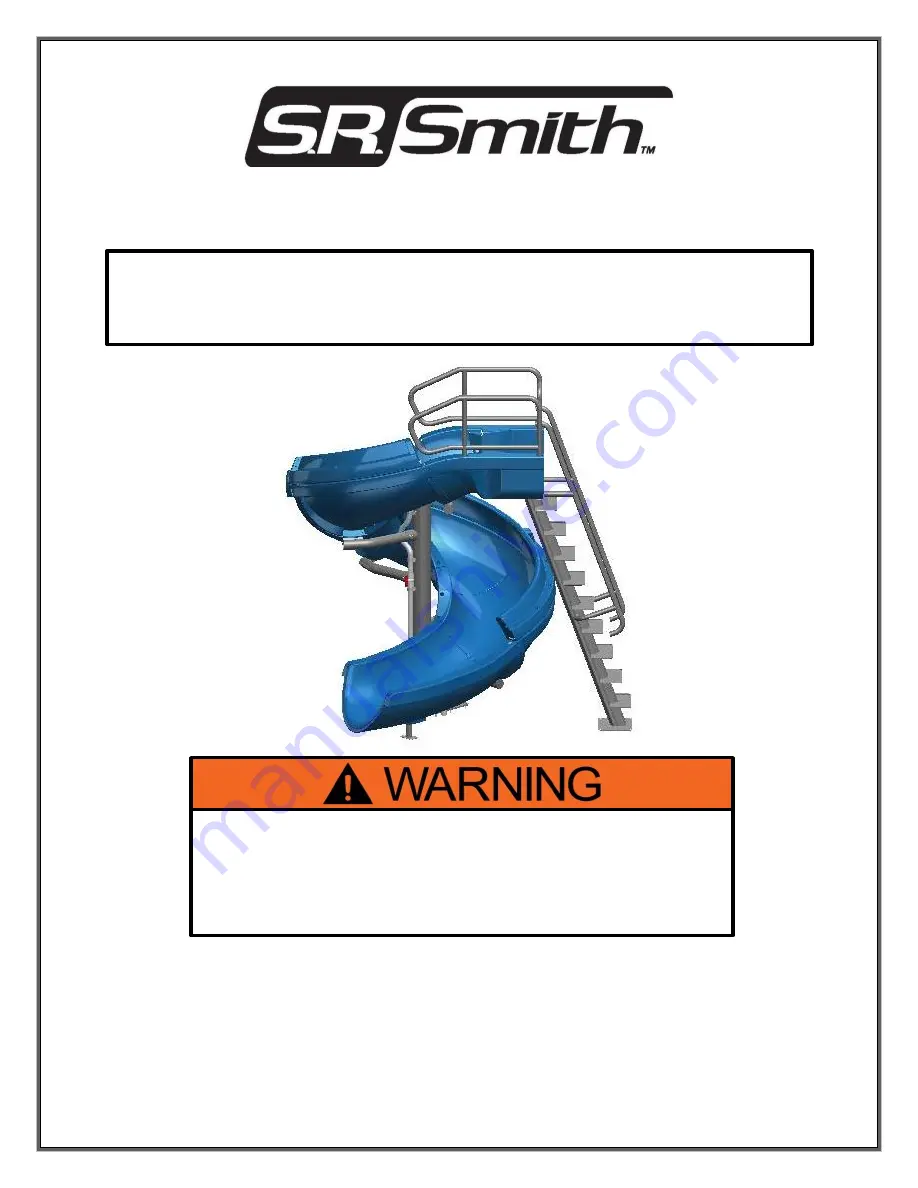

VORTEX

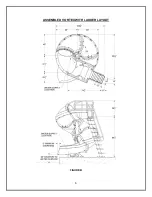

ASSEMBLY AND INSTALLATION

INSTRUCTIONS

SRS AUSTRALIA, PTY LTD

12 Enterprise St

Richlands QLD 4077

Australia

Phone 07 3812 2283 • Fax 07 3812 1187

www.srsmith.com/au

S.R. SMITH, LLC

CORPORATE HEADQUARTERS

P.O. Box 400 • 1017 S.W. Berg Parkway

Canby, Oregon 97013

USA

Phone (503) 266 2231 • Fax (503) 266 4334

www.srsmith.com

S.R. SMITH VORTEX SLIDES ARE MANUFACTURED FOR INSTALLATION

AND USE ON INGROUND SWIMMING POOLS ONLY. THE VORTEX IS

NEVER TO BE INSTALLED AND USED ON ABOVEGROUND POOLS,

ONGROUND POOLS, HOUSEBOATS, BOAT DOCKS, FLOATING DOCKS

OR PLATFORMS OR OTHER BODIES OF WATER SUCH AS LAKES,

PONDS, RIVERS, ETC.