Summary of Contents for FCA 201

Page 1: ...Ref S FR 266 11 19 Models FCA 201 601 AIR COOLED MODULAR CHILLER ...

Page 6: ...Page 5 Operating Range Cooling ...

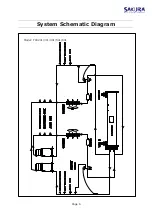

Page 7: ...System Schematic Diagram Page 6 Model FCA201 301 401 501 601 ...

Page 17: ...Dimensions Page 16 Model FCA201 301 Model FCA401 ...

Page 18: ...Page 17 Model FCA501 601 ...

Page 25: ...Page 24 FCA201 301 401 501 601 Maintenance Maintenance ...