© Samsung Electronics Co.,Ltd. Apr. 2002

Printed in Korea

AD68-00564E

DIGITAL CAMCORDER

SCD80/D86/D87

SERVICE

1. Precautions

2. Product Specifications and

Comparison Chart

3. Disassembly and Reassembly

4. Alignment and Adjustment

5. Exploded View and Parts List

6. Electrical Parts List

7. PCB Diagrams

8. Wiring Diagram

9. Schematic Diagrams

Manual

DIGITAL CAMCORDER

CONTENTS

For mechanical disassembly and adjustment, refer to the “Mechanical Manual”

(CSM2000 AD68-30200A).

Summary of Contents for SCD80

Page 5: ...MEMO MEMO Products Specifications and Comparison Chart Samsung Electronics 2 2 ...

Page 15: ...Samsung Electronics 3 10 Disassembly and Reassembly MEMO MEMO ...

Page 43: ...Samsung Electronics 4 28 Alignment and Adjustment MEMO MEMO ...

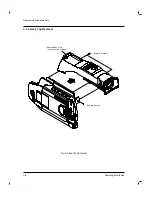

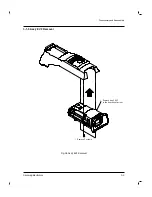

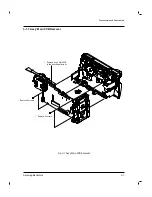

Page 45: ...Samsung Electronics 5 2 Exploded View and Parts List 5 1 Ass y CASE REAR ...

Page 57: ...Samsung Electronics 5 14 Exploded View and Parts List 5 7 Ass y LCD 580 581 ...

Page 59: ...Samsung Electronics 5 16 Exploded View and Parts List 5 8 Ass y CAMERA 152 ...

Page 61: ...Samsung Electronics 5 18 Exploded View and Parts List 5 9 Ass y CVF 519 ...

Page 63: ...Samsung Electronics 5 20 Exploded View and Parts List 5 10 Ass y EVF ...

Page 69: ...Samsung Electronics 5 26 Exploded View and Parts List MEMO MEMO ...

Page 87: ...MEMO MEMO Samsung Electronics 6 18 Electrical Parts List ...

Page 89: ...7 2 Samsung Electronics PCB Diagrams 7 1 MAIN PCB Component Side ...

Page 90: ...7 3 Samsung Electronics PCB Diagrams Conductor Side ...

Page 91: ...7 4 Samsung Electronics PCB Diagrams 7 2 CVF PCB Component Side Conductor Side ...

Page 92: ...7 5 Samsung Electronics PCB Diagrams 7 3 CCD PCB Component Side Conductor Side ...

Page 93: ...7 6 Samsung Electronics PCB Diagrams 7 4 JACK PCB Component Side Conductor Side ...

Page 94: ...7 7 Samsung Electronics PCB Diagrams 7 5 TOP PCB Component Side Conductor Side ...

Page 95: ...7 8 Samsung Electronics PCB Diagrams 7 6 FUNCTION PCB ...

Page 96: ...7 9 Samsung Electronics PCB Diagrams 7 7 PVI LCD PCB ...

Page 97: ...7 10 Samsung Electronics PCB Diagrams 7 8 Sony LCD PCB Component Side Conductor Side ...

Page 98: ...7 11 Samsung Electronics PCB Diagrams 7 9 EVF PCB Component Side Conductor Side ...

Page 99: ...7 12 Samsung Electronics PCB Diagrams 7 10 REAR PCB Component Side Conductor Side ...

Page 100: ...7 13 Samsung Electronics PCB Diagrams 7 11 LEFT PCB Component Side Conductor Side ...

Page 101: ...7 14 Samsung Electronics PCB Diagrams 7 12 Memory Stick PCB Component Side Conductor Side ...

Page 103: ...8 2 Samsung Electronics Wiring Diagram MEMO MEMO ...

Page 105: ...9 2 Samsung Electronics Schematic Diagrams 9 1 System Control ...

Page 106: ...9 3 Samsung Electronics Schematic Diagrams 9 2 Servo ...

Page 107: ...9 4 Samsung Electronics Schematic Diagrams 9 3 Timer ...

Page 108: ...9 5 Samsung Electronics Schematic Diagrams 9 4 Camera ...

Page 109: ...9 6 Samsung Electronics Schematic Diagrams 9 5 DC DC Converter ...

Page 110: ...9 7 Samsung Electronics Schematic Diagrams 9 6 Audio ...

Page 111: ...9 8 Samsung Electronics Schematic Diagrams 9 7 Video ...

Page 112: ...9 9 Samsung Electronics Schematic Diagrams 9 8 USB ...

Page 113: ...9 10 Samsung Electronics Schematic Diagrams 9 9 CVF ...

Page 114: ...9 11 Samsung Electronics Schematic Diagrams 9 10 EVF ...

Page 115: ...9 12 Samsung Electronics Schematic Diagrams 9 11 PVI LCD ...

Page 116: ...9 13 Samsung Electronics Schematic Diagrams 9 12 Sony LCD ...

Page 117: ...9 14 Samsung Electronics Schematic Diagrams 9 13 CCD ...

Page 118: ...9 15 Samsung Electronics Schematic Diagrams 9 14 TOP BLOCK SCHEMATIC ...

Page 119: ...9 16 Samsung Electronics Schematic Diagrams 9 15 FUNCTION BLOCK SCHEMATIC ...

Page 120: ...9 17 Samsung Electronics Schematic Diagrams 9 16 JACK ...

Page 121: ...9 18 Samsung Electronics Schematic Diagrams 9 17 REAR ...

Page 122: ...9 19 Samsung Electronics Schematic Diagrams 9 18 LEFT ...

Page 123: ...9 20 Samsung Electronics Schematic Diagrams 9 19 Memory Stick 1 ...

Page 124: ...9 21 Samsung Electronics Schematic Diagrams 9 20 Memory Stick 2 ...

Page 125: ...MEMO MEMO 9 22 Samsung Electronics Schematic Diagrams ...

Page 157: ...1 30 Samsung Electronics MEMO 1 동작 영문 2001 7 4 2 4 PM 페이지1 30 ...