!

o

Operating Instructions

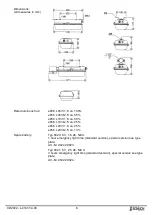

Explosion-proof LED-Emergency Light Fitting

with built-in battery

Series e856…

The safety of people and equipment in hazardous areas depends on the

observance of all safety standards. Exact knowledge about all applicable

regulations and standards is mandatory for installation maintenance and

repair of explosion proof equipment, especially

the determinations of IEC/EN 60079-14 and IEC/EN 60079-17 for

maintenance of explosion-proof appliances

the generally accepted rules of the technical side

the national rules for prevention of accidents and for safety standards

the safety instructions of these operating instructions

the characteristic data on the type plate and the instruction plates