Summary of Contents for 2004 GTX 4-TEC Supercharged 6159

Page 1: ...C M Y CM MY CY CMY K www SeaDooManuals net ...

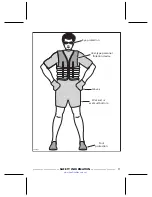

Page 8: ...SAFETY INFORMATION ____________ SAFETY INFORMATION ____________ 7 www SeaDooManuals net ...

Page 30: ...VEHICLE INFORMATION _____________________ 29 www SeaDooManuals net ...

Page 88: ...MAINTENANCE INFORMATION _____________________ 87 www SeaDooManuals net ...

Page 122: ...WARRANTY _____________________ 121 www SeaDooManuals net ...