InstructIons for:

mobile drum handler 205ltr

MoDEL no :

dh02.V2

thank you for purchasing a sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SaFetY inStruCtionS

IMPORTANT:

PleaSe read theSe inStruCtionS CareFullY. note the SaFe oPerational reQuirementS, WarninGS and

CautionS. uSe the ProduCt CorreCtlY and With Care For the PurPoSe For WhiCh it iS intended. Failure to do So maY

CauSe damaGe and/or PerSonal inJurY and Will inValidate the WarrantY. PleaSe KeeP inStruCtionS SaFe For Future uSe.

2. introduCtion & SPeCiFiCation

Before use inspect the drum handler for damage and worn

components.

If in any doubt do not use and have inspected/repaired by an

authorised service agent.

only use the drum handler on firm, level, unobstructed surfaces

which are capable of supporting the handler and drum.

do not

overload the drum handler - maximum capacity is

360kg.

do not

ride or

allow others to ride on the drum handler.

do not

use on tarmacadam. the drum handler must only be

used on a concrete surface.

replace or repair damaged parts.

Use only recommended parts.

Unauthorised parts may be dangerous and will invalidate the

warranty.

use a qualified person to lubricate and maintain the drum handler.

WarninG!

failure to comply with these instructions may result

in loss of load, damage to drum handler or other property and/or

personal injury.

Ideal for manoeuvring, relocating and draining fully loaded drums.

Lever handle raises drums in stages with fingertip-operated locks.

Adjustable for reach/leverage and clamp height. clips on both sides

hold drum secure in vertical or horizontal positions. Drum can be

manually adjusted and held at any angle or, if contents need mixing,

can be turned end-over-end. Handler is fitted with two, smooth-

rolling, heavy-duty wheels and one castor. suitable for 205ltr drums.

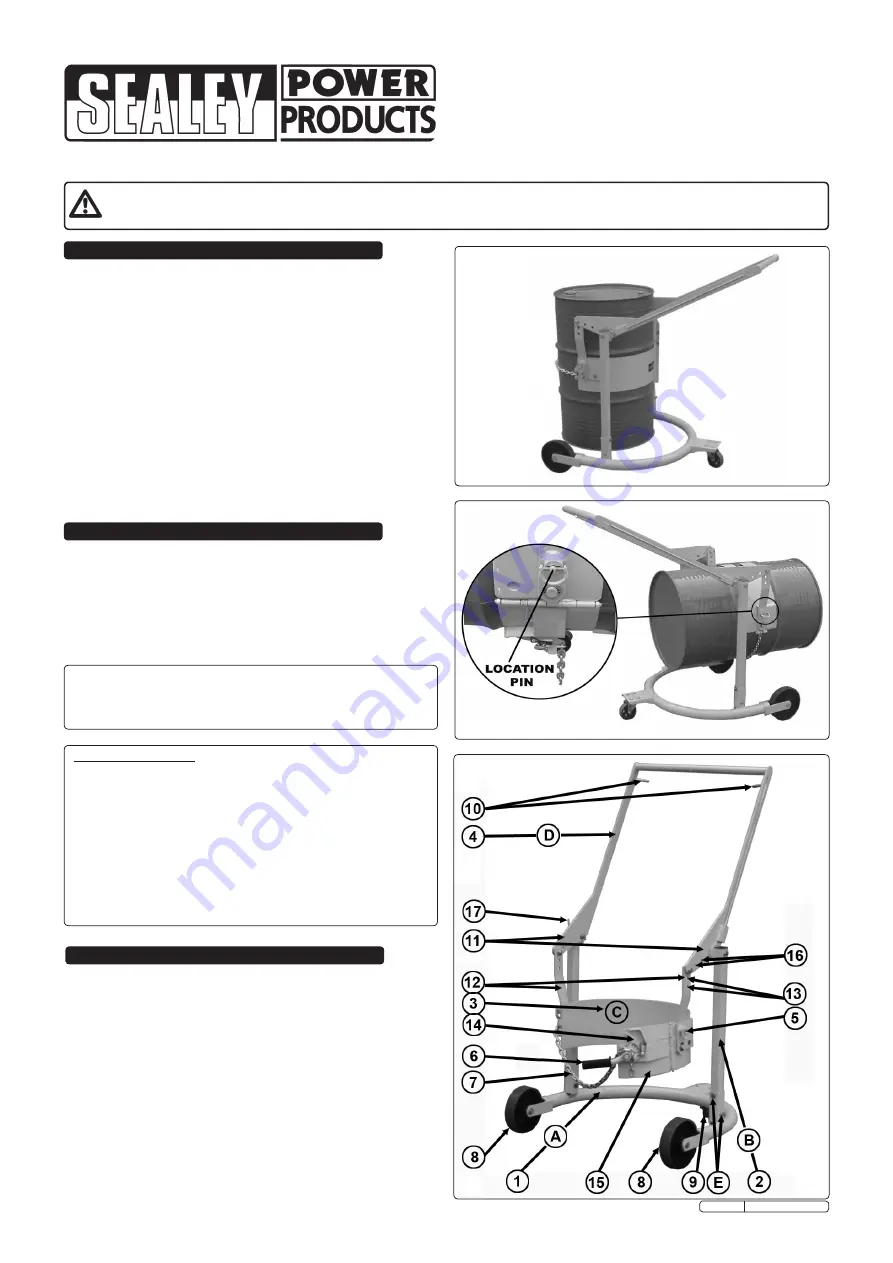

3. aSSemblY

3.1

remove the sub-assemblies from packaging in following order.

a

chassis (fig.3.1).

b

Mast (fig.3.2).

C

supporting Hoop (fig.3.3).

d

Handle (fig.3.4).

e

Washers, nuts and clamp collars.

3.2

Assemble mast (B) x 2 onto chassis (A) with the screws,

washers and nuts provided (E).

3.2.1 Bolt the handle (D) to the masts (B). see (fig.3.11).

3.2.2 Attach the hangers (fig.3.12) on the supporting hoop

assembly (c) onto the lifting arms (fig.3.11) on the handle

(D) and secure with bolts provided.

refer to parts diagram for additional guidance.

Specification

Drum size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205 litres

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50kg

Lifting Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360Kg

Figure 3 reference

item description

1

chassis

2

Mast

3

supporting Hoop

4

Handle

5

Location Pin

6

fastening Lever

7

chain

8

Wheel

9

caster

10

Location Lever

11

Lifting Arm

12

Hanger Plate

13

Adjustment Hole

14

Pawl

15

Hinged Hoop

16

Adjustment Hole

17

Hook

Fig.1

Fig.2

Fig.3

Original Language Version

DH02.V2 Issue: 2 - 15/03/10