RecipRocating Saw 850w/230V

Model no:

SRS850

thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. Safety

1.1.

eLectRicaL Safety

waRning!

It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and

all electrical connections for wear and damage. Sealey recommend that an RCd (Residual Current device) is used with all electrical

products. You may obtain an RCd by contacting your local Sealey dealer.

if the product is used in the course of business duties, it must be maintained in a safe condition and routinely PAT (Portable

Appliance Test) tested.

electrical safety information, it is important that the following information is read and understood.

1.1.1.

ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

1.1.2.

Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

1.1.3.

important

: Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is fitted with the

correct fuse - see fuse rating in these instructions.

8

Do not

pull or carry the appliance by the power cable.

8

Do not

pull the plug from the socket by the cable. Remove the plug from the socket by maintaining a firm grip on the plug.

8

Do not

use worn or damaged cables, plugs or connectors. ensure that any faulty item is repaired or replaced immediately by a

qualified electricia

n.

1.1.4.

This product is fitted with a BS1363/A 13 Amp 3 pin plug.

If the cable or plug is damaged during use, switch the electricity supply and remove from use.

Replace a damaged plug with a BS1363/A 13 Amp 3 pin plug. If in doubt contact a qualified electrician.

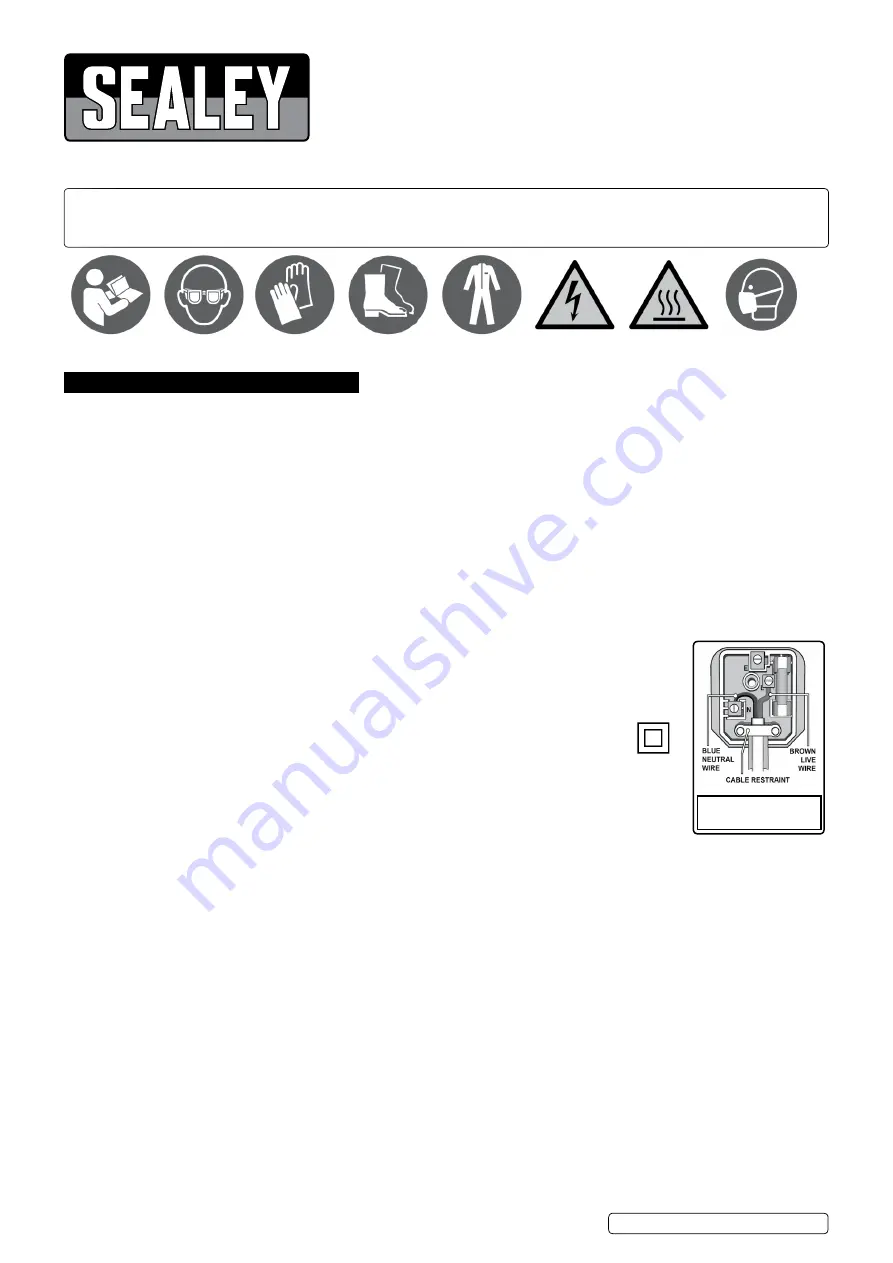

Class II products are wired with live (brown) and neutral (blue) only are marked with the

Class II symbol;

A) Connect the BROWN live wire to the live terminal ‘L’.

B) Connect the BLUE neutral wire to the neutral terminal ‘N’.

C) After wiring, check that there are no bare wires and ensure that all wires have been correctly

connected.

ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

8

Do not

connect either wire to the earth terminal.

Sealey recommend that repairs are carried out by a qualified electrician.

1.2.

geneRaL Safety

9

Stay alert, watch what you are doing and use common sense when operating a power tool.

8

Do not

use a power tool while you are tired or under the influence of drugs, alcohol or medication.

9

Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

9

Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking

up or carrying the tool.

9

Remove any adjusting key or wrench before turning the power tool on.

8

Do not

overreach. Keep proper footing and balance at all times.

8

Do not

wear loose clothing or jewellery. Keep your hair and clothing away from moving parts. loose clothes, jewellery or long hair

can be caught in moving parts.

9

The use of a dust extraction system may reduce dust-related hazards.

8

Do not

let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles.

8

Do not

force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer

at the rate for which it was designed.

8

Do not

use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is

dangerous and must be repaired.

9

Disconnect the plug from the power source and / or the battery pack, if detachable, from the power tool before making any

adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the

power tool accidentally.

9

Store idle power tools out of the reach of children and

Do not

allow persons unfamiliar with the power tool or these instructions to

operate the power tool. Power tools are dangerous in the hands of untrained users.

9

Maintain power tools and accessories carefully. Check for misalignment or binding of moving parts, breakage of parts and any other

Recommended fuse rating

13 Amp

S

RS850 Issue 1 28/09/18

Original Language Version

© Jack Sealey limited

Refer to

instructions

electrical shock

hazard

Hot surfaces

Wear eye

protection

Wear protective

gloves

Wear safety

footwear

Wear protective

clothing

Wear a mask