Thank you very much for purchasing our LED lighting fittings.

Please read this instruction manual to use the product properly.

1) Prior to installing the fitting, check if the product is as per your order.

2) Check for a loose or damaged part due to an accident in transit, etc.

1) The electrical characteristic data is given below.

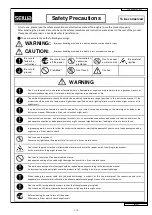

- Installation work should be done properly by a qualified electrician in accordance with the related laws and the instruction manual.

- For safety, Installation work should be done by at least two workers.

■

Lighting fitting for inside inspection

NB1:

NB2: The mounting brackets are optionally available.

For further i for atio , see Optio : Mou ti g Bracket.

NB:

NB1: Use M8 or larger bolts to mount it on the structure.

NB2:

LCTD1101

81

-N

(5000K)

IP65

Please perform connection of power wires and insulating.

The colors of power wire are white and red. The color of earth

wire is black.

Vapor Tight Type LED Lighting Fittings

LCTD

After installing the product, be sure to hand this manual over to the user of the product.

Model

100-242V AC

50 / 60Hz

Input

Current

Power

Consumption

IP

rating

Mount the lamp house with the attached mounting brackets

on the structure (tank inspection hole, etc.) firmly.

Fig.1

81M -W

11E0001151A11

To be conserved

Instruction Manual

Option

(3000K)

Input Voltage

(Frequency)

0.16-0.07A

When the supplied cross-recessed pan head machine

screws are used, the recommended thickness of the

mounting bracket is 2 to 5 mm.

Mounting Bracket

-M

Prior to use

Performance

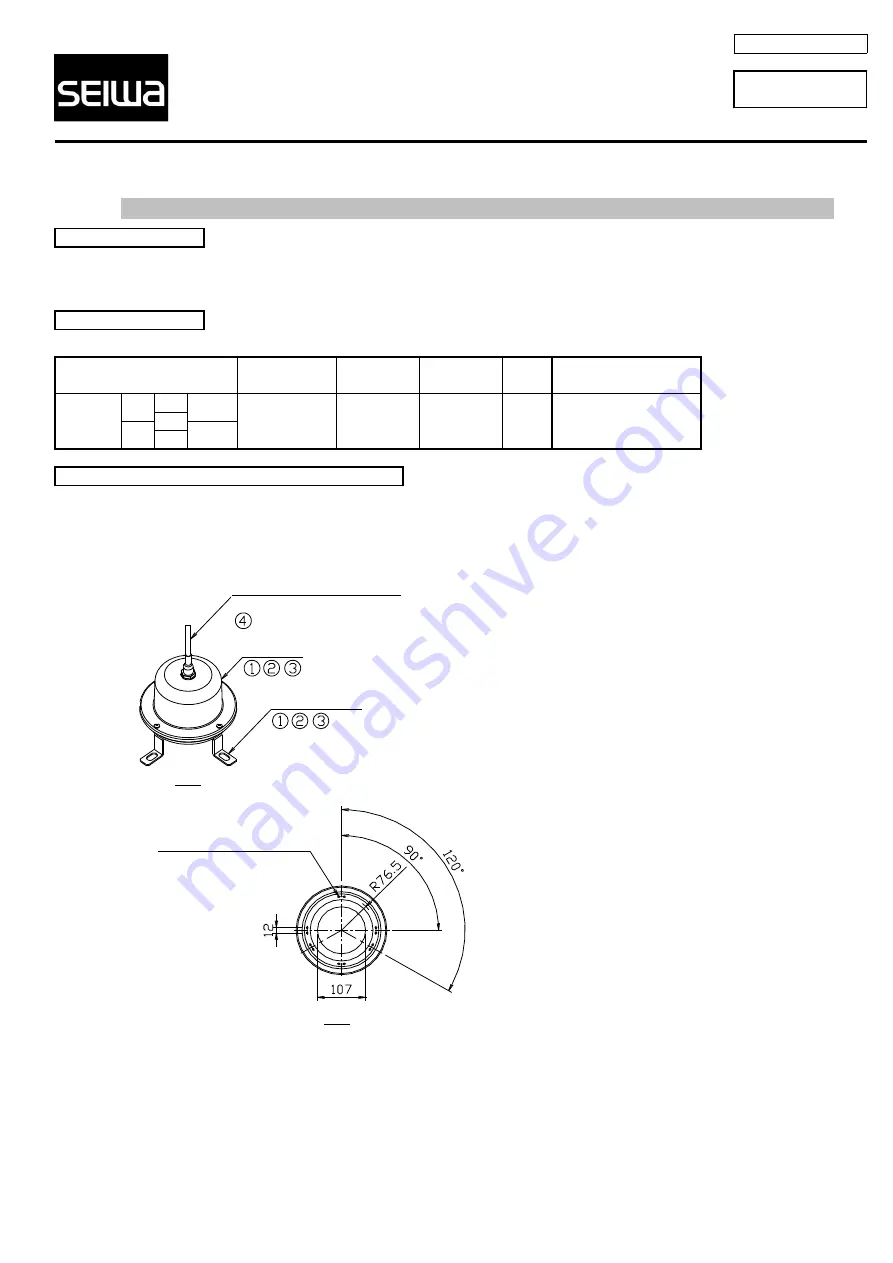

Prepare robust mounting brackets to be attached to the lamp

house (fitting) referring to the figure on the right (mounting

hole positions).

Attach and fix the mounting brackets at four places (90 °

pitch) or three places (120° pitch).

Among the 12 cross-recessed pan head machine screws

(M5x12, with plain and spring washers) on the lamp house,

remove as many ones as needed. After removal, attach the

mounting brackets to the lamp house using as many cross-

recessed pan head machine screws as needed.

15.0-15.5W

Names of the Components and Installation Method

Be sure to fix the mounting brackets and lamp house firmly

using the mounting screw holes, though the mounting

bracket height (distance from the tank inspection hole,

etc.) is not limited.

Fig.2

CABLE

HVCT 1.25mm

2

×

3C

(2m)

Mounting bracket (option)

(not supplied)

Lamp house fittings

2

×

6-M5 Mounting screw

holes

Screw

hole depth:8

12 cross-recessed pan head machine screw

M5

×

12

with spring and plain washers(supplied)

- -