Security Engineered Machinery Co., Inc

OPERATIONAL & MAINTENANCE MANUAL

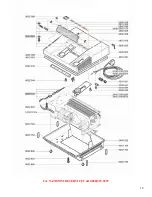

SEM Model 2226CC/3-No Oiler

Serial Number 6321943 and Up

POP-0013 Rev. 1

Revised 05/15/2013

Security Engineered Machinery Co., Inc

NATIONWIDE SERVICE

Phone Toll Free 1(800)225-9293

Email:

Service@SEMSHRED.COM

Fax: (508)366-6814

Website:

WWW.SEMSHRED.com

Summary of Contents for 2226CC/3

Page 16: ...For NATIONWIDE SERVICE Call 1 800 225 9293 16 ...

Page 17: ...For NATIONWIDE SERVICE Call 1 800 225 9293 17 ...

Page 18: ...For NATIONWIDE SERVICE Call 1 800 225 9293 18 ...

Page 19: ...For NATIONWIDE SERVICE Call 1 800 225 9293 19 ...

Page 20: ...For NATIONWIDE SERVICE Call 1 800 225 9293 20 ...

Page 21: ...For NATIONWIDE SERVICE Call 1 800 225 9293 21 ...

Page 22: ...For NATIONWIDE SERVICE Call 1 800 225 9293 22 ...