GUARDING SYSTEM

INSTALLATION MANUAL

600, 900, 1200 GUARDING

Patented Design

AS/NZS

4024.3610

STRENGTH

TESTED

EASY

INSTALLATION

MODULAR

SYSTEM

COST SAVING

UP TO 30%

A PRODUCT OF

Safety & General

Information

This Installation Manual is provided as an assembly guide for the Sentry Guarding System. Refer to the

Design Guide for recommended layouts for various job site conditions. The product may be unstable

during installation until fully assembled. Proper safety measures must be taken at all times. Product may

fail and void warranty if installation does not comply with standards, design guide and drawings.

Sentry Guarding System has been designed and tested to comply with:

AS/NZS 4024.3610 - Safety of Machinery - Conveyors.

Tools

• 17mm ring spanner

• Riveter Blindnut Kit (M10)

• Rivet Gun

• 6mm Hex Key

Personal Protective Equipment

• Safety Glasses

• Protective Gloves

• Safety Footware

Equipment Required:

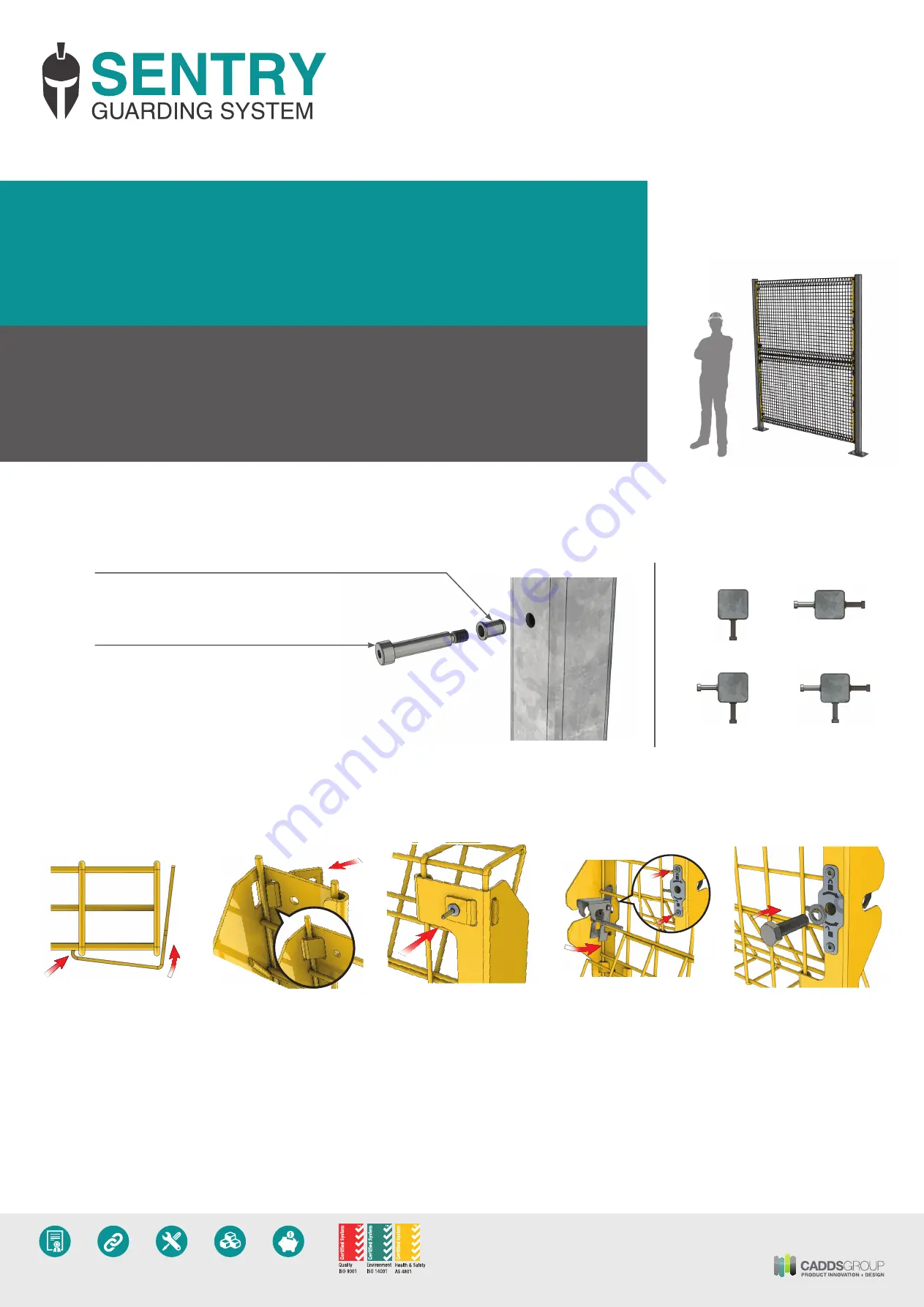

Step 1

Install M10 Rivet nut using Blindnut Riveter.

Step 2

Tighten mild steel shoulder bolt M10 x 12 x 50LG /

Stainless Steel shoulder bolt (Part No:

SGS10-12-50SS

)

to 44.7Nm using hex key.

Note: Mild Steel shoulder bolt should be hot dip

galvanised in place with post.

POST ASSEMbLY

GUARDING ASSEMbLY

Post Configurations:

90

°

layout

180

°

layout

T - layout

Single layout

b

A

Step 1

Engage all bracket hooks

onto wire mesh B and

swing bracket to align

with the side of the mesh

panel.

Step 3

Secure mesh locking tabs

using 6.4 stainless steel

rivets (Ø4.8mm, 6.4mm

grip).

Step 4

Slide top tab of latch

assembly between wire

mesh and bracket.

Locate front washer on

front face and secure with

6.4 stainless steel rivets.

Step 5

Screw M10 bolt with

spring washer, half way

into latch assembly.

Step 2

Insert all four mesh

locking tabs into allocated

slots.