Owner’s Manual

HVE3000 Flood Pumper and Inline Booster

#633 - 115V

Manufactured by Sapphire Scientific for Servpro Industries, Inc.

15180 Josh Wilson Road, Burlington, WA 98233

Phone: 800-932-3030

Fax: 360-757-7950

www.SapphireScientific.com

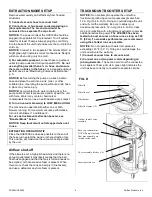

The high-efficiency HVE3000 can be used both as a flood pumper to quickly remove excess

liquid water for flood remediation and as an inline truckmount booster to extend the

effective vacuum hose length for carpet extraction and cleaning.

Patents:

R E A D A N D S A V E T H E S E I N S T R U C T I O N S

SAFETY INSTRUCTIONS

WARNING! Do not alter or modify your HVE3000 in

any way. Use only replacement parts authorized by

Sapphire Scientific, Inc. Modifications or use of

unapproved parts could create a hazard and will

void your warranty. Contact your authorized

Sapphire distributor for assistance.

WARNING! Do not operate unit in standing water.

Electric shock hazard. Unit must be grounded.

WARNING! Unit must be grounded.

•

Keep motor and wiring dry. Keep out of standing

water and do not install in area likely to be subject to

water intrusion. Do not expose to rain, water or

snow.

•

Insert three-prong plug on power cord into a

matching electrically grounded outlet. Do not use

adapter. Never cut off third prong.

•

Do not use an extension cord.

•

To reduce the risk of fire or electric shock, do not

use this unit with any solid-state speed control

device.

FIRE HAZARD

•

Keep away from open flames and heat sources.

•

Do not use or store where vapors from gasoline,

solvents, thinners or other flammable materials may

be present.

WARNING! Unplug unit before cleaning or servicing

.

•

Turn off unit and unplug before lifting or moving.

•

Handle the unit carefully. Always operate the unit on

a stable, level surface. Do not drop, throw, or place

where it could fall. Rough treatment can damage the

unit, and may create a hazardous condition or void

the warranty.

•

Inspect the power cord before use. If cord is

damaged, do not use. Always grasp the plug (not

the cord) to unplug.

•

The unit must be operated on a 115V/60 Hz circuit

protected by a Ground Fault Circuit Interrupter

(GFCI) device.

•

Do not attempt to repair the unit. For authorized

service options, contact SERVPRO

®

RMA

Department at 866-885-6833 or email

rma@servpronet.com.

BEFORE YOU BEGIN

Warranty registration

To process a warranty or repair claim, just click the

“

RMA/ Warranty Form

” listed under the “Products” tab

on the

Servpro

NET

®

home page or it is also found at the

Equipment page on

Servpro

NET.

You may contact the SERVPRO

®

RMA Department by

phone at 866-885-6833 or via email at

rma@servpronet.com.

To expedite the warranty claim process, please have the

following:

•

Equipment model number.

•

Serial number.

•

Usage hours (if applicable).

When Franchises purchase equipment from Servpro

Industries, Inc. unit date of purchase and serial numbers

are recorded on the invoice. As part of the Servpro

Industries, Inc. RMA/Warranty program, proof of

purchase and equipment warranty records are added to

WARNING

SP004 HVE3000

1

Dri-Eaz Products, Inc.