INSTALLATION MANUAL

Parts marked with "

" are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

SHARP CORPORATION

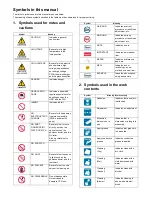

Transit, Installation (using) environment, Note

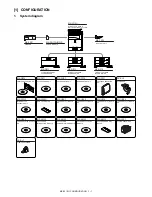

[1]

CONFIGURATION . . . . . . . . . . . . . . . . 1-1

[2]

MX-2310U (MAIN UNIT). . . . . . . . . . . . 2-1

[3]

Dehumidifying heater . . . . . . . . . . . . . . 3-1

[4]

MX-DE12/DE13/DE14

(STAND/1x500/2x500/3x500 SHEET

PAPER DRAWER) . . . . . . . . . . . . . . . . . 4-1

[5]

AR-SU1 (STAMP UNIT) . . . . . . . . . . . . 5-1

[6]

MX-FN17 (FINISHER) . . . . . . . . . . . . . 6-1

[7]

MX-PN11A/B/C/D (PUNCH MODULE). . 7-1

[8]

MX-TR12 (EXIT TRAY UNIT) . . . . . . . 8-1

[9]

MX-FX11 (FACSIMILE EXPANSION KIT) . 9-1

[10] MX-SM10

(EXPANSION MEMORY BOARD). . . 10-1

[11] MX-PF10 (BARCODE FONT KIT). . . 11-1

[12] MX-FR25U (DATA SECURITY KIT) . . 12-1

[13] MX-PB14 (PRINTER EXPANSION KIT) . . 13-1

[14] MX-PUX1 (XPS EXPANSION KIT) . . 14-1

[15] MX-PK11 (PS3 EXPANSION KIT) . . 15-1

[16] MX-FWX1

(INTERNET FAX EXPANSION KIT) . 16-1

[17] MX-AMX1

(APPLICATION INTEGRATION

MODULE) . . . . . . . . . . . . . . . . . . . . . 17-1

[18] MX-AMX2

(APPLICATION COMMUNICATION

MODULE) . . . . . . . . . . . . . . . . . . . . . 18-1

[19] MX-AMX3

(EXTERNAL ACCOUNT MODULE) . . 19-1

[20] Remote operation panel function

Enable setting . . . . . . . . . . . . . . . . . . 20-1

[21] Setting, Adjustments, Operation check . . 21-1

[22] Setup and adjustment data recording . . . 22-1

[23] Necessary works before moving the

machine . . . . . . . . . . . . . . . . . . . . . . 23-1

CONTENTS

CODE: 00ZMX2310/I1E

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM

MX-2310U

MODEL