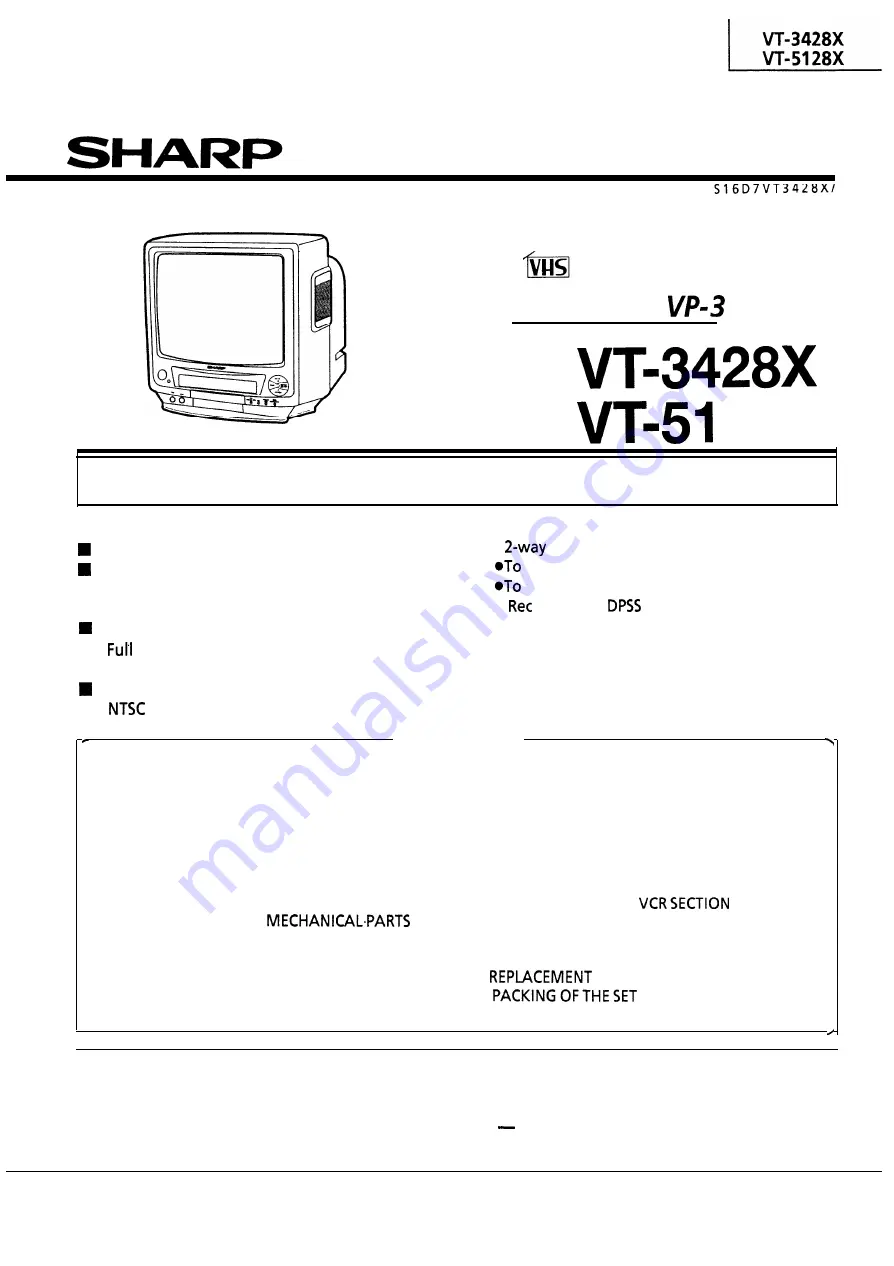

SERVICE

MANUAL

TV/VCR COMBINATION

VIDEO TV

C h a s s i s N o .

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be

restored to its original condition and only parts identical to those specified should be used.

FEATURES

TV/VCR Integration for Easy Operation

Single Built-in Tuner for Simple Operation

n

Timer Programme Setting by the On-Screen

Display

Auto Tracking Control

n

Auto Head Cleaning System

n

On-screen Display with Menu Screen Guidance

Wake-Up/Sleep Timer

n

Simple Playback

n

Child-Proof Lock

Lock Operation Mode

Lock the Power Off.

n

Index with

(Digital Programme Search

System)

n

Full Auto Play Function

n

Auto Repeat Playback

n

Front input terminals Audio/Video

CONTENTS

Page

l

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . .

2

l

IMPORTANT SERVICE NOTES . . . . . . . . . . . . .

3

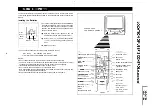

. LOCATION OF USER’S CONTROL . . . . . . . . .

4

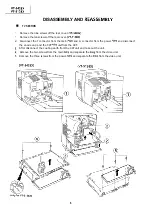

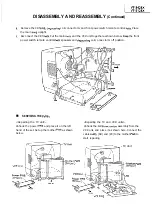

. DISASSEMBLY AND REASSEMBLY . . . . . . . .

6

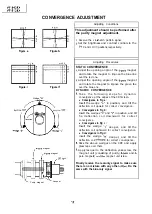

. ADJUSTMENT OF THE TV ELECTRICAL .

CIRCUITRY . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

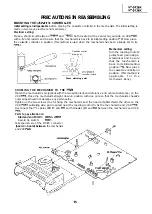

. PRECAUTIONS IN REASSEMBLING . . . . . . .

15

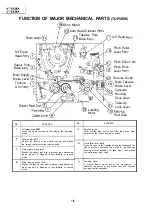

. FUNCTION OF MAJOR

16

. ADJUSTMENT, REPLACEMENTAND

ASSEMBLY OF MECHANICAL PARTS

ADJUSTMENT OF THE VCR ELECTRICAL.. ..

18

.

CIRCUITRY . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42

. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . .

45

Page

l

OVERALL SCHEMATIC DIAGRAM . . . . . . . .

57

l

CHASSIS LAYOUT OF TV SECTION . . . . . . .

59

. BLOCK DIAGRAM OF TV SECTION . . . . . . .

61

. DESCRIPTION OF TV SECTION

SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . .

65

. CHASSIS LAYOUT OF VCR SECTION . . . . . .

79

l

BLOCK DIAGRAM OF

. . . . . .

81

. DESCRIPTION OF VCR SECTION

SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . .

91

. PRINTED WIRING BOARD ASSEMBLIES . . .

97

.

PARTS LIST

. . . . . . . . . . . .

105

.

. . . . . . . . . . . . . . . . .

134

WARNING

The

chassis in this receiver

is partially hot. Use an isolation transformer between the line cord plug and

power receptacle, when servicing this chassis.

To prevent electric shock, do not remove cover. No user

qualified service personnel.

serviceable parts inside. Refer servicing to

SHARP CORPORATION

Summary of Contents for VT-3428X

Page 78: ...m 3428X VT 51 28X IF Pack Unit RiWOOl7CEZZ 1 4 11 l e i t 1 I 2 I 3 I 4 I 5 I 6 1 78 ...

Page 82: ...VT 3428X VT 5128X I AWIO m I Au 10 f X I 7 I 8 I 9 I 10 I 11 I 12 I 82 ...

Page 90: ...VT 3428X VT 51 28X I t 7 I 8 I 9 I 10 I 11 I 12 I ...

Page 94: ...VT 3428X W 5128X 3 7 I 8 I 9 I 10 I 11 I 12 I 94 ...

Page 96: ...VT 3428X VT 51 28X TO Y C AUDIO CIRCUIT NCR 21 I I I I 7 I 8 I 9 I 10 I 11 I 12 I 96 ...

Page 100: ...m 3428X VT 51 28X Wiring Side f r 7 I 8 I 9 I 10 I 11 I 12 1 100 ...

Page 102: ...VT 3428X VT 51 28X I 7 I 8 I 9 I 10 I 11 102 1 12 I ...

Page 104: ...VT 3428X I m 5128X 1 7 I 8 I 9 I 10 I 11 I 12 I ...

Page 123: ...MECHANISM CHASSIS PARTS G F E I i 1 I 2 I 3 I 4 I 5 I 6 I 123 ...

Page 125: ...CASSETTE HOUSING CONTROL PARTS i T 3428X VT 51 28X 1 I 2 I 3 I 4 I 5 I 6 I 125 ...

Page 127: ...VT 3428X W 51 28X MODIEL VT 3428X CABINET AND MECHANICAL PARTS 1 I 2 I 3 I 4 I 5 I 6 127 ...

Page 128: ...W 3428X VT 51 28X I IO 9 0 3 7 128 ...

Page 130: ...VT 3428X VT 5128X I 0 I 0 ...

Page 132: ...MODELS VT 3428X AND VT 51 28X CABINET AND MECHANICAL PARTS I i 1 I 2 I 3 I 4 I 5 I 6 I 132 ...

Page 136: ...S H A R P TQ0023 S Printed in Japan 0 w s MW KD ...