Summary of Contents for SC90

Page 2: ......

Page 16: ...14 419050 B Simrad SC90 ...

Page 219: ...419050 B 217 Øverland UPC 3005 Dimensions Cable layout and interconnections ...

Page 223: ...419050 B 221 Øverland UPC 5000P Dimensions Cable layout and interconnections ...

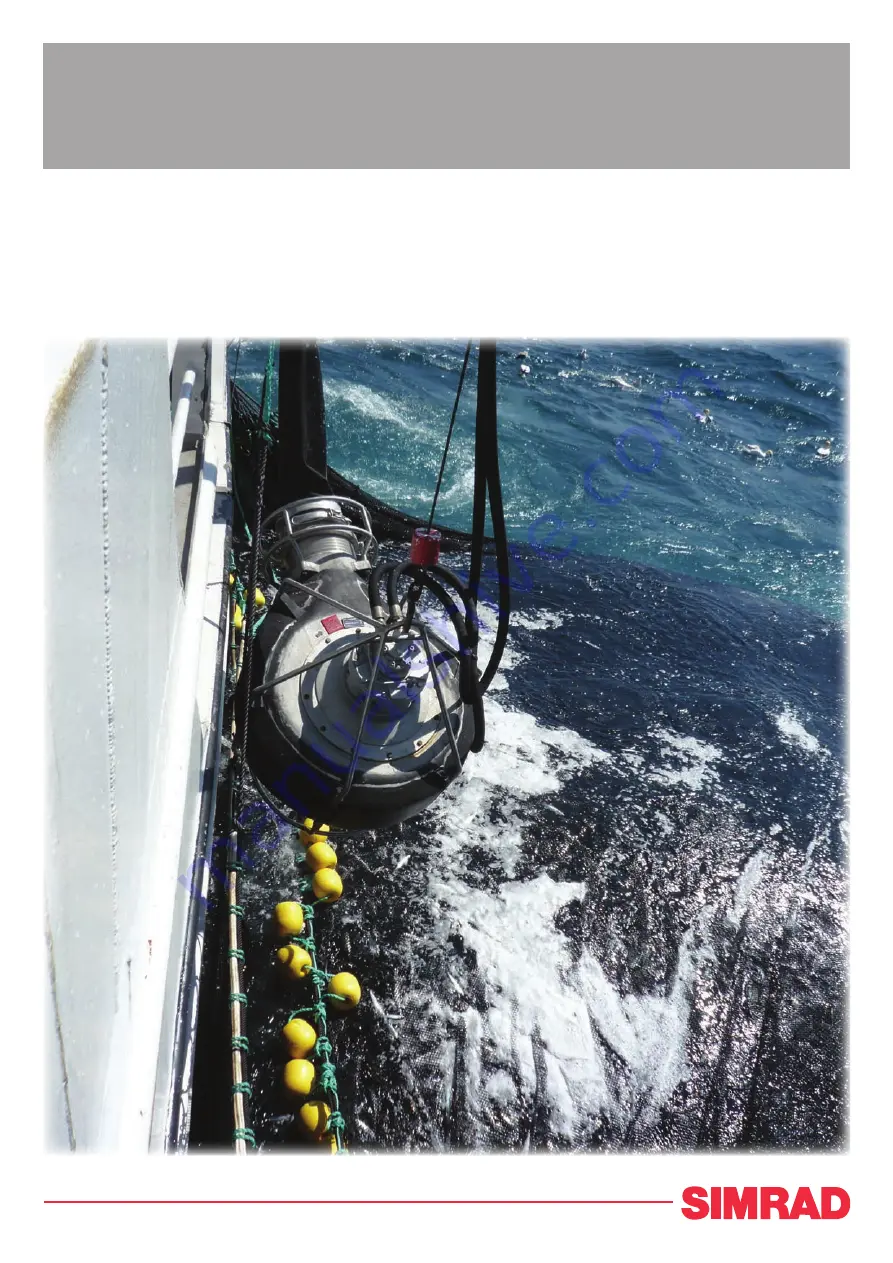

Page 438: ...436 419050 B 427177 Transducer dock dimensions page 494 Simrad SC90 Installation Manual ...

Page 441: ...419050 B 439 Drawing file ...

Page 442: ...440 419050 B Simrad SC90 Installation Manual ...

Page 445: ...419050 B 443 Drawing file ...

Page 452: ...450 419050 B Simrad SC90 Installation Manual ...

Page 455: ...419050 B 453 Drawing file ...

Page 458: ...456 419050 B Simrad SC90 Installation Manual ...

Page 463: ...419050 B 461 Drawing file ...

Page 468: ...466 419050 B Simrad SC90 Installation Manual ...

Page 469: ...419050 B 467 Related topics Installing the optional gate valve DN350 page 84 Drawing file ...

Page 471: ...419050 B 469 Drawing file ...

Page 473: ...419050 B 471 214043 Gate valve installation DN350 Drawing file ...

Page 475: ...419050 B 473 422915 Gate valve installation DN350 Drawing file ...

Page 477: ...419050 B 475 083045 Gate valve installation DN500 Drawing file ...

Page 479: ...419050 B 477 33414 Gate valve dimensions DN350 Drawing file ...

Page 480: ...478 419050 B Simrad SC90 Installation Manual ...

Page 481: ...419050 B 479 Related topics Installing the optional gate valve DN350 page 84 Drawing file ...

Page 482: ...480 419050 B 33473 Gate valve dimensions DN350 Simrad SC90 Installation Manual ...

Page 483: ...419050 B 481 Related topics Installing the optional gate valve DN350 page 84 Drawing file ...

Page 484: ...482 419050 B 33498 Gate valve dimensions DN500 Simrad SC90 Installation Manual ...

Page 485: ...419050 B 483 Drawing file ...

Page 487: ...419050 B 485 37357 Gate valve dimensions DN500 Drawing file ...

Page 488: ...486 419050 B Simrad SC90 Installation Manual ...

Page 489: ...419050 B 487 Related topics Installing the optional gate valve DN500 page 103 Drawing file ...

Page 491: ...419050 B 489 Drawing file ...

Page 494: ...492 419050 B Simrad SC90 Installation Manual ...

Page 495: ...419050 B 493 Related topics Installing the optional gate valve DN350 page 84 Drawing file ...

Page 497: ...419050 B 495 Drawing file ...

Page 542: ... 2018Kongsberg Maritime ISBN xxx ...

Page 543: ......

Page 544: ...Simrad SC90 Fish finding sonar Installation Manual ...