CAUTION!

Wear appropriate PPE when working with chemicals. Backflow prevention required.

!

Venturi Sanitize Rinse Foam

Quick Start Guide

M2448 - SLX-MS3-VS-RN-VF Quick Start Guide

Last Updated: 04/12/2022

A. Take hold of spray wand for the system

B. Open discharge ball valve

C. Open water supply valve - unit will spray

D. Verify water pressure is

at least

35 PSI

E. [Foamers] Open air supply valve - unit will foam

F. [Foamers] Adjust air pressure to alter foam quality

G.

Foam equipment, from bottom to top, and rinse

before it dries

H.

Rinse from top to bottom

I.

When complete, turn off supply valves

J. Store rinsed hose depressurized, with discharge

valve open, and coiled properly to prevent kinks

3

Operation

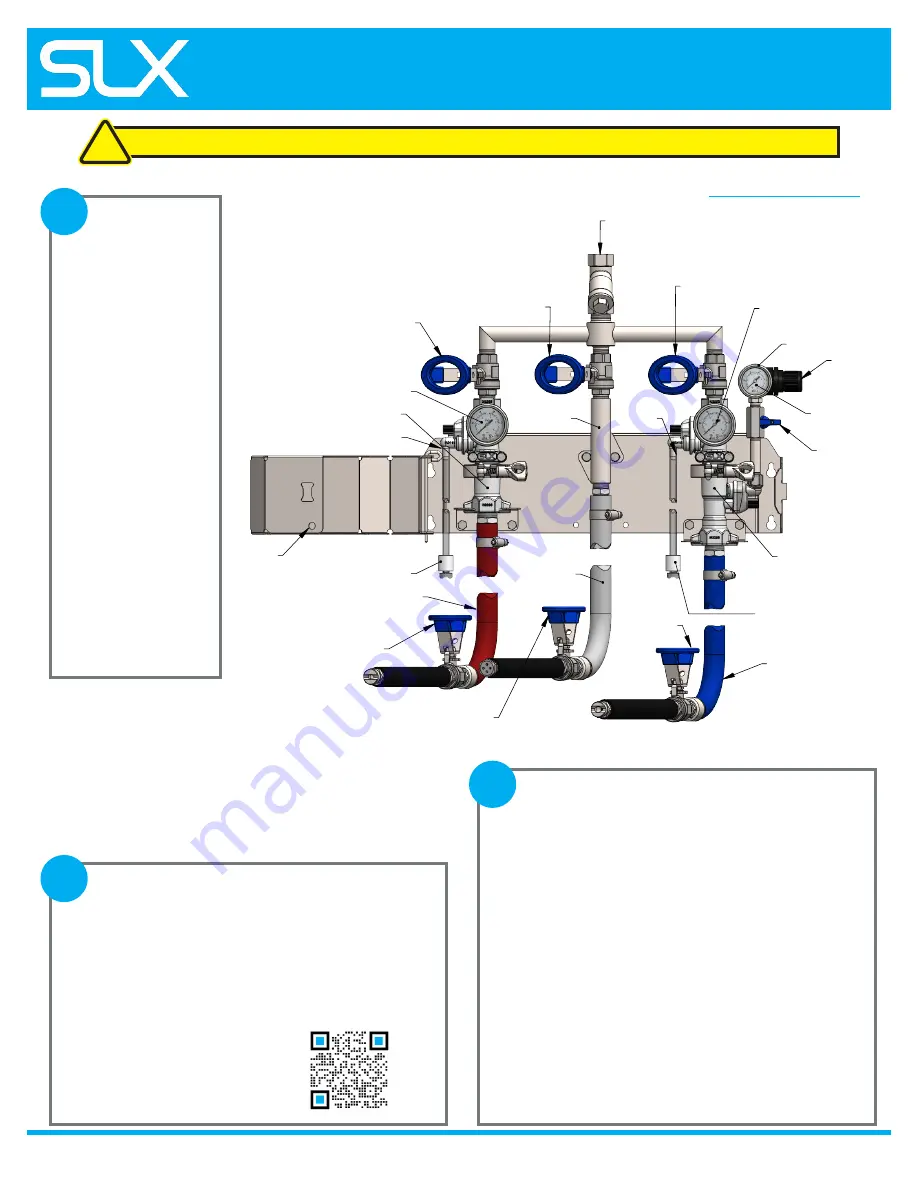

WATER SUPPLY (35 - 125psi)

3/4

" NPT CONNECTION

AIR SUPPLY (1/4" NPT)

AIR PRESSURE

GAUGE

AIR

REGULATOR

AIR SUPPLY

BALL VALVE

FOAMER SUPPLY

BALL VALVE

RINSE SUPPLY

BALL VALVE

FOAMER WATER

PRESSURE GAUGE

DOOR LOCK

FOAMER SOLUTION LINE

WITH STRAINER &

CERAMIC WEIGHT

FOAMER

RINSE

STATION

FOAMER DISCHARGE HOSE

RINSE

DISCHARGE

HOSE

FOAMER

DISCHARGE

BALL VALVE

RINSE DISCHARGE

BALL VALVE

FOAMER

CHEMICAL

INLET

SANITIZER

DISCHARGE

BALL VALVE

SANITIZER DISCHARGE HOSE (RED)

SANITIZER SOLUTION LINE WITH

STRAINER & CERAMIC WEIGHT

SANITIZER

SANITIZER CHEMICAL INLET

SANITIZER WATER PRESSURE GAUGE

SANITIZER SUPPLY BALL VALVE

Example Installation

A.

Select a metering tip for desired dilution ratio

B.

Install the metering tips by screwing it onto the hose

barbs for each chemical inlet

C.

Install chemical suction lines to hose barbs

D.

Connect suction lines to chemical solution

2

Dilution

Metering Tip Calculator

Mobile App:

A. Mount SLX

enclosure to wall

B. Flush supply lines

C.

Install backflow

prevention per

local guidelines

D. Connect supply

lines:

• Compressed air

(1/4” NPT)

• Water (3/4”

NPT)

E. Connect discharge

hoses

F. Place chemical

containers below

unit

1

Install &

Connect