®

If you have a problem, question, or request, call

your local dealer, or Steelcase Line 1 at

888.STEELCASE

(888.783.3522)

for immediate action by people who want to help you.

(Outside the U.S.A., Canada, Mexico, Puerto Rico,

and the U.S. Virgin Islands, call: 1.616.247.2500)

Or visit our website: www.steelcase.com

©

2014 Steelcase Inc.

Grand Rapids, MI 49501

U.S.A.

Printed in U.S.A.

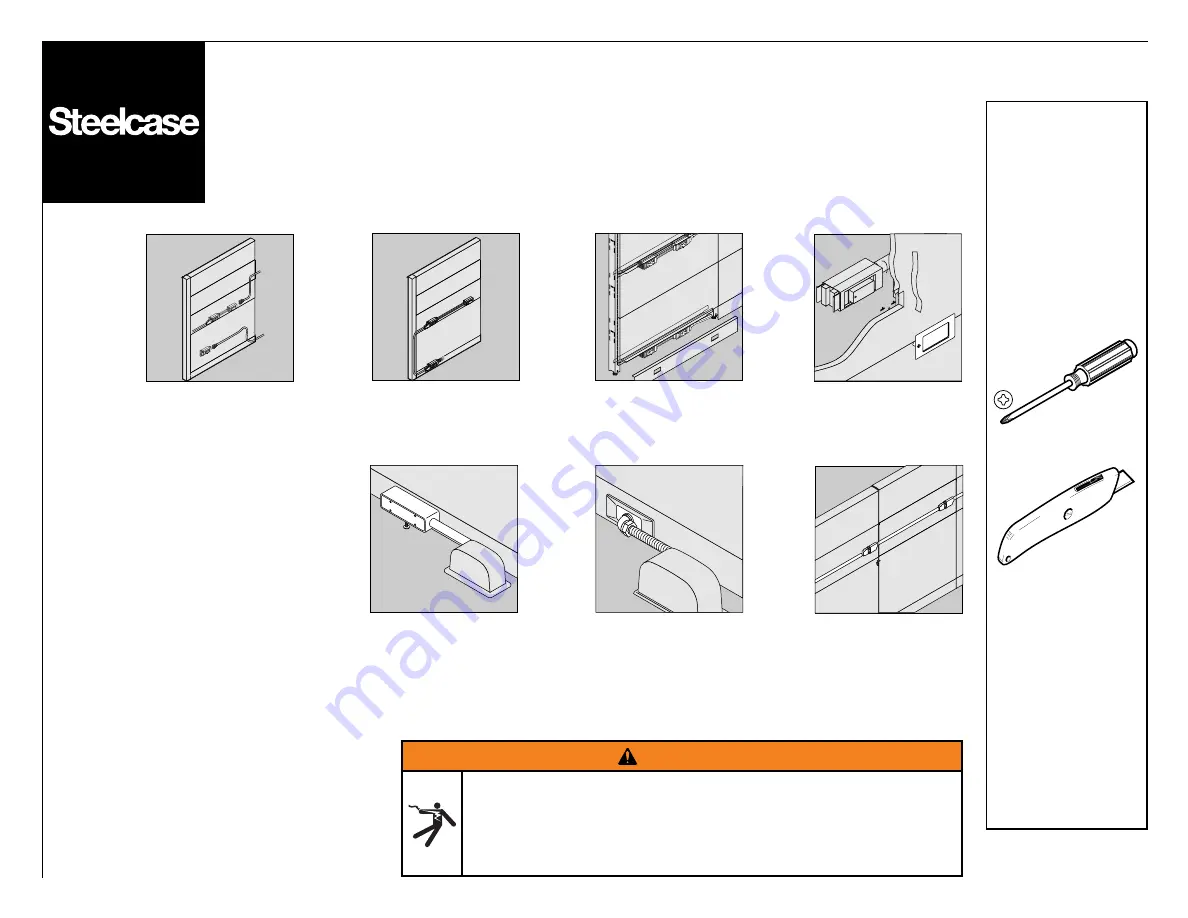

Answer

®

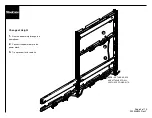

Modular Power

Standard Power In

Feed - Floor

Receptacle Covers

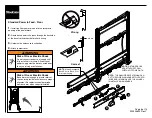

New York Power In

Feed - Floor

Pass Thru Power

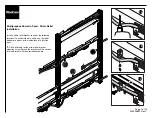

Power Kits

Change of Height

Harness

NOTE:

Unused modular electrical

connector openings are not required

to be capped.

NOTE:

The electrician can cut conduit

and wire to length if needed.

Page 1 of 10

939504633 Rev Y

Risk of Fire or Electric Shock

• All electrical installations should be performed by a qualified person in

accordance with codes and regulations applicable at the installation site.

Circuits should be checked for proper voltages. All sources of power

supply must be disconnected prior to any servicing or installation.

WARNING

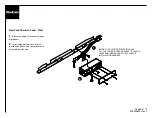

Multipurpose Power

In Feed