INSTRUCTION MANUAL

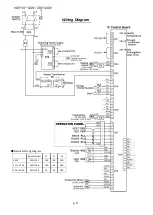

MODEL

:

iQ-400

MACHINE No.:

IMPORTANT

DO NOT DESTROY

Read carefully and understand this INSTRUCTIONS before

operating your Strapack machine.

Keep this booklet in a convenient location for use at any time.

This machine is conformity with the requirement of the following EC Directive ,

2006/42/EC Machinery Directive

2014/30/EU EMC Directive

iQ400-1A-02001-00

(Mar 2018)

ORIGINAL INSTRUCTION

800-821-2177

Service@MillerBevco.com or Parts@MillerBevco.com

www.MillerBevco.com