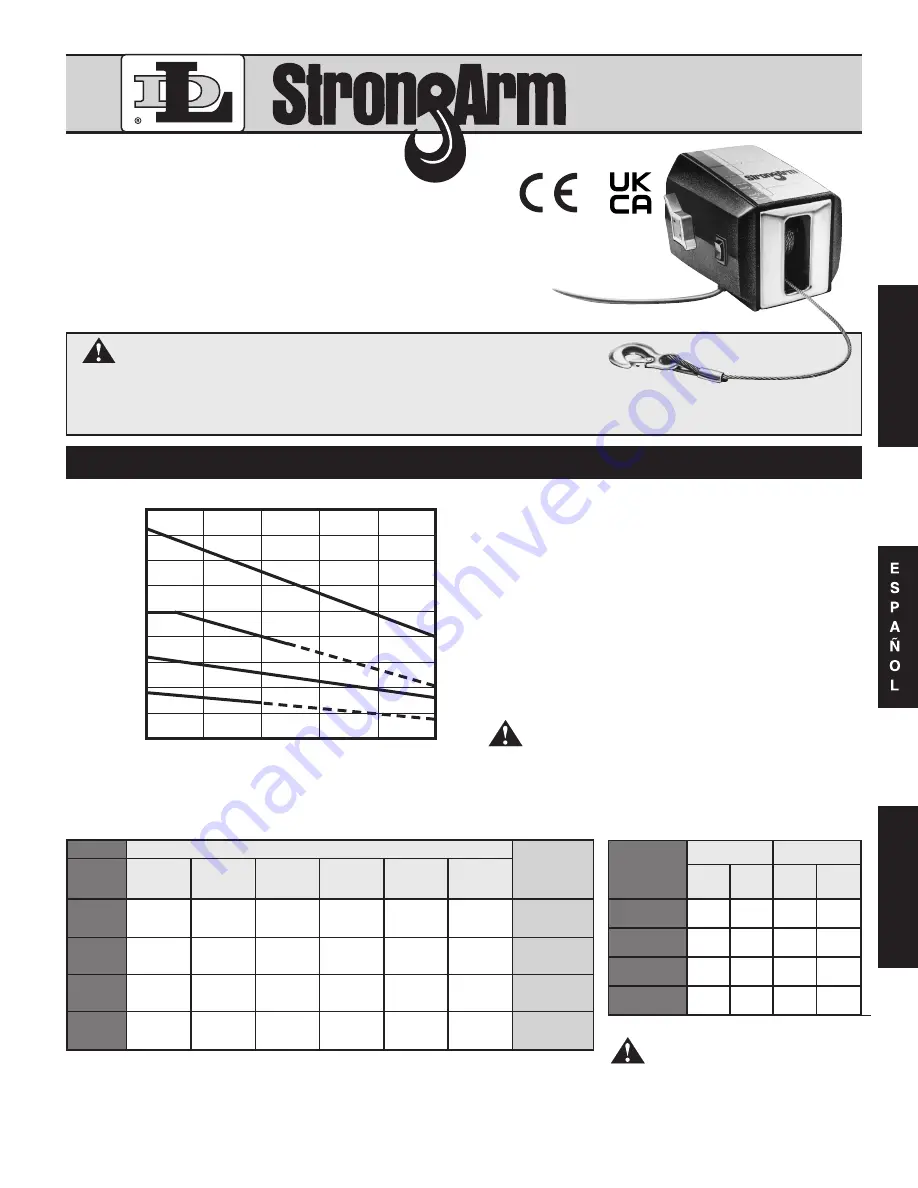

ELECTRIC WINCH RATING*

5% 10% 20% 30% 50% 70%

(3°) (6°) (11°) (17°) (26°) (35°)

8,000 lbs. 6,000 lbs. 4,000 lbs. 3,100 lbs. 2,200 lbs. 1,800 lbs. 1,200 lbs.

3,629 kg 2,722 kg 1,814 kg 1,406 kg 998 kg 816 kg

544 kg

12,000 lbs. 9,000 lbs. 6,100 lbs. 4,600 lbs. 3,300 lbs. 2,700 lbs. 1,800 lbs.

5,443 kg 4,082 kg 2,767 kg 2,087 kg 1,497 kg 1,225 kg

817 kg

18,000 lbs. 13,500 lbs. 9,100 lbs. 6,900 lbs. 5,000 lbs. 4,100 lbs. 2,700 lbs.

8,165 kg 6,124 kg 4,128 kg 3,130 kg 2,268 kg 1,860 kg

1,225 kg

26,700 lbs. 20,100 lbs. 13,600 lbs. 10,300 lbs. 7,400 lbs. 6,100 lbs. 4,000 lbs.

12,111 kg 9,117 kg 6,169 kg 4,672 kg 3,357 kg 2,767 kg

1,814 kg

120 Volt AC

ELECTRIC WINCHES

®

DOUBLE LINE OPERATION

Models SA7000AC, SA7015AC, SA12000AC and

SA12015AC are factory equipped with a pulley

block and hook and 50’ of cable for double line

operation. This increases the pulling capacity of the

winch as shown, however, care must be taken to

allow adequate motor cooling. Note that with dou-

ble line, a pull of 25’ requires reeling in 50’ of cable.

For intermittent use only. Ratings at left are based

on 10’ pull. For longer pulls motor cooling periods

must be allowed.

MAXIMUM CONTINUOUS RUN TIME 3 MINUTES

CAUTION: CONTINUOUS RUNNING IN

EXCESS OF 3 MINUTES WILL DAMAGE WINCH

MOTOR.

GUIDE TO ROLLING LOAD CAPACITY**

Maximum weight in pounds and kilograms rolling load.

APPROXIMATE LOAD

SPEED

(FT./MIN.)

MODEL

PERCENT INCLINE

LOAD

CAPACITY*

(*) Load capacity (dead weight) is a measure of actual maximum force to which the

winch system may be subjected.

(**) All capacities shown are with 15’ of cable on the reel and 10% rolling friction factor.

For full reel of cable adjust capacities according to graph above. Note 5% incline is

one-half foot rise in ten feet.

WINCH RATINGS

OWNER’S

MANUAL

MODELS SA5000AC, SA5015AC,

SA7000AC, SA7015AC, SA9000AC,

SA9015AC, SA12000AC, SA12015AC

5000

4500

4000

3500

3000

2500

2000

1500

1000

500

DEAD WEIGHT CAPACITY (LBS.)*

LENGTH OF CABLE ON REEL (FT.)

10

20

30

40 50

SA9000AC & SA9015AC single line

SA12000AC & SA12015AC double line

SA7000AC & SA7015AC double line

SA5000AC & SA5015AC single line

WARNING: NOT TO BE

USED AS A HOIST FOR

LIFTING, SUPPORTING OR

TRANSPORTING PEOPLE OR

LOADS OVER AREAS WHERE

PEOPLE COULD BE PRESENT!

NO LOAD FULL LOAD

Full Empty Full Empty

Reel Reel Reel Reel

35 16 16 9

17.5 8 9.5 6

18 6 7 3.5

9 3 4 2

WARNING:

READ INSTRUCTIONS CAREFULLY BEFORE

ATTEMPTING TO INSTALL, OPERATE OR SERVICE THE STRONGARM

ELECTRIC WINCH. FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT

IN SERIOUS OR FATAL INJURY. RETAIN INSTRUCTIONS FOR FUTURE REFERENCE.

E

N

G

L

I

S

H

F

R

A

N

Ç

A

I

S

1

SA5000AC

SA5015AC

SA7000AC

SA7015AC

SA9000AC

SA9015AC

SA12000AC

SA12015AC

SA5000AC

SA5015AC

SA7000AC

SA7015AC

SA9000AC

SA9015AC

SA12000AC

SA12015AC