1

WARRANTY NOTES

1) The utmost care is taken at Thorley Headers to maintain the highest standards of quality.

However, Thorley Headers cannot control the installation of the product. For this reason, the

Thorley Headers warranty covers only the replacement of the components - not the labor for

the installation.

2) The use of any type of “header wrapping” voids the warranty. Using any sort of wrapping

material on the headers destroys the tubing’s ability to dissipate heat, causing very rapid

deterioration of the metal and the subsequent failure of the headers.

3) The chrome plating applied to all Thorley headers is a high-nickel chrome finish applied to

retard corrosion. This is a “heat” chrome to preserve the metal. This finish is not “show

chrome” intended for the sake of appearance. This high-nickel chrome turns colors and

approaches black as it cooks into the metal. The brilliance of the chrome finish is not cov-

ered under the warranty. Contamination of the surface by foreign substances may produce

other color patterns. This can be prevented by routine cleaning.

B Y

S U M M I T

I N D U S T R I E S

THY-470

NISSAN/ SUZUKI 4.0L

FRONTIER, PATHFINDER, XTERRA/

EQUATOR, 2005-12, 2/4WD

2 - M10x1.25x35mm Hex flange bolts

2 - M10X1.25 Hex flange nuts

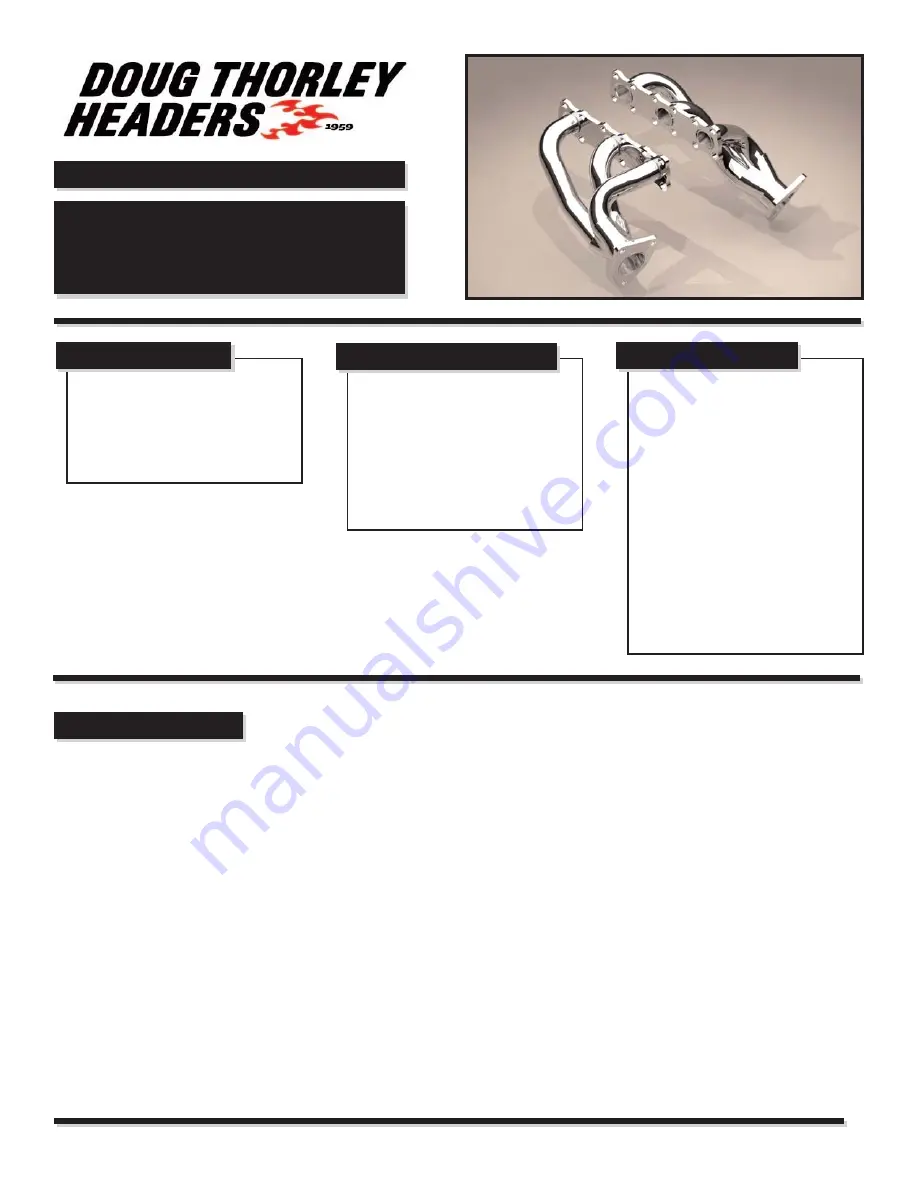

1 - Driver side Header Assembly

1 - Pass. side Header Assembly

PARTS INCLUDED

HARDWARE INCLUDED

TOOLS REQUIRED

12mm, 14mm Wrenches

12mm, 14mm Deep sockets

12mm, 14mm Regular sockets

Ratchet and extensions

Pliers

Crescent wrench

Torque wrench

Rust penetrant

High-temp sensor-safe silicon sealer

(rated at 600 )