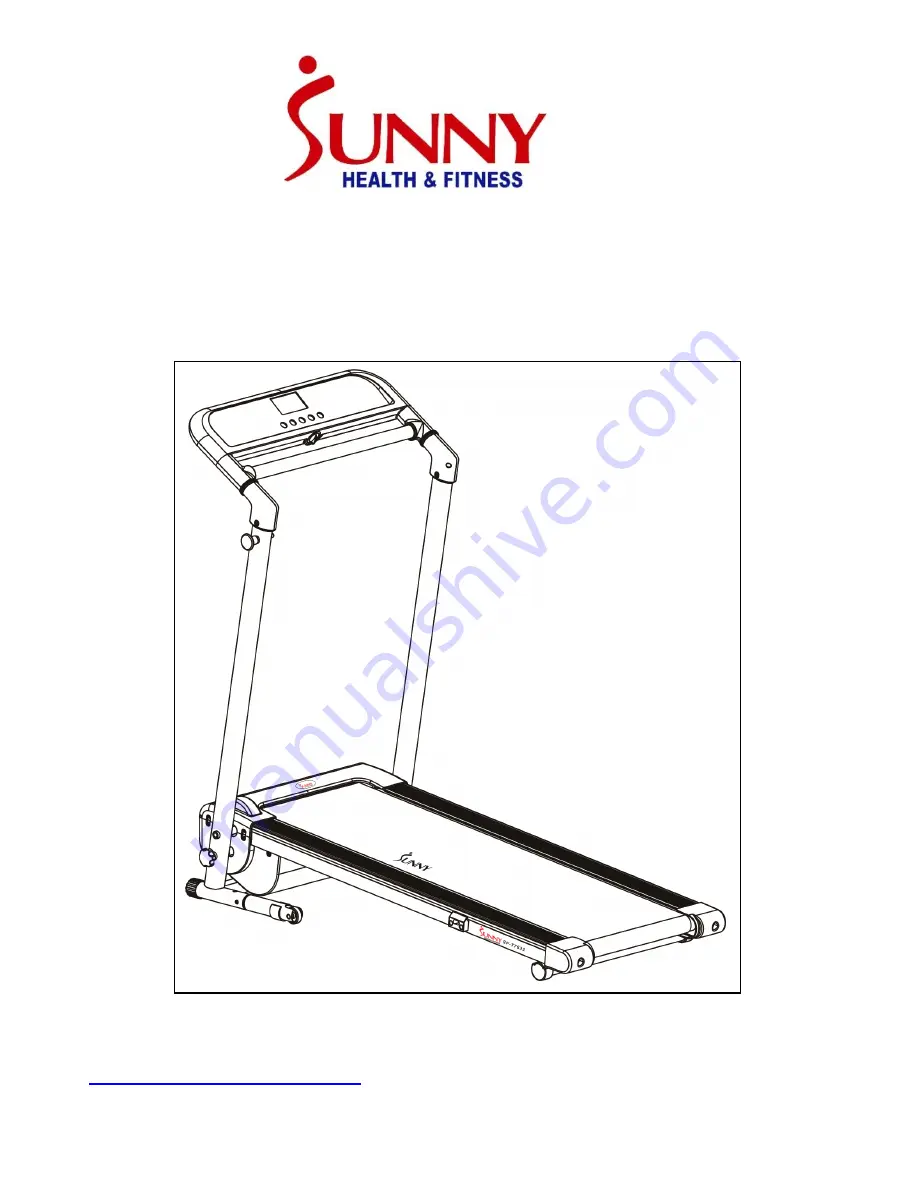

SPACE SAVING FOLDING TREADMILL

SF-T7632

USER MANUAL

IMPORTANT!

Please retain owner

’s manual for maintenance and adjustment instructions. Your

satisfaction is very important to us,

PLEASE DO NOT RETURN UNTIL YOU HAVE CONTACTED

US

support@sunnyhealthfitness.com

or 1- 877 - 90SUNNY (877-907-8669).

Summary of Contents for SF-T7632

Page 5: ...4 EXPLODED DIAGRAM ...