1

Copyright 2019 Thermoplastic Comfort Systems, Inc.

Operation Instructions: TCS Duplicating Unit Model TC105

www.tcsdentalinc.com / 866-426-2970

I112012 Rev D

Effective Date: 11/12/19

tcs®

tcs®

Duplicating

Unit

Model #3611-01

I

0

tcs® DUPLICATING UNIT

Warnings

Manufactured in the U.S.A.

• Read Instructional Manual prior to use.

• DO NOT plug in unit without adding 100% PURE ANTIFREEZE.

Do not substitute antifreeze.

• Maintain antifreeze level

(approx half full according to glass indicator on side of unit).

• When filling the unit with Duplicating Paste unplug the motor from

the control box.

• Replug motor to control box after lid is securely on unit.

• Ready for use when red light temperature reads 130 degrees.

• This unit is designed to be left ON at all times.

C A U T I O N

H O T S U R F A C E

L111412 RE

V NE

W

PV

SV

SEL <

^

^

The TCS Duplicating Unit uses antifreeze

in a double boiler design. This engineering

spares the hydrocolloid paste from

sticking to the sides of the tank and

burning. This unit is meant to be kept "on"

at all times so that you have paste ready

when you need it.

Item #3614-01 (110V)

**W A R N I N G**

DO NOT PLUG IN

until filled with 100% pure Antifreeze. Running the unit without

antifreeze

immediately burns the heating element

and

voids the warranty.

tcs®

tcs®

Duplicating

Unit

Model #3611-01

I

0

tcs® DUPLICATING UNIT

Warnings

Manufactured in the U.S.A.

• Read Instructional Manual prior to use.

• DO NOT plug in unit without adding 100% PURE ANTIFREEZE.

Do not substitute antifreeze.

• Maintain antifreeze level (approx half full according to glass indicator on side of unit).

• When filling the unit with Duplicating Paste unplug the motor from

the control box.

• Replug motor to control box after lid is securely on unit.

• Ready for use when red light temperature reads 130 degrees.

• This unit is designed to be left ON at all times.

C A U T I O N

H O T S U R F A C E

L111412 RE

V NE

W

A

B

C

D

E

F

G

H

B

C

ProG

rUn

PV

SV

Manufac

tured in the U

.S.A.

L111412 RE

V NE

W

I

J

K

L

Important things to know about your machine:

• This unit is pre-calibrated as follows: Once the program cycle is set to “run” (refer to instruction) and the melt down begins it will take 20 minutes to reach

its calibrated high temperature of 194°F. The unit will remain at the high temperature for 1 hour and 10 minutes as it melts the paste. The unit will then

automatically begin to cool to the holding temperature of 130°F, this will take approximately 2 hours. It will remain at this temperature at all times until all

the paste is used and you are ready to run a new cycle.

• This unit is designed to be “on” at all times.

• At the beginning of the melt down cycle the mixer will make very slight turning movements, however, as the paste begins to melt, the mixer will turn

faster. The mixer is designed to turn periodically in small increments once it is at holding temperature. The double boiler protects the paste from burning.

• If the default parameters are not working for your type of paste, e.g. lumpy paste, refer to FAQ to change parameters or contact TCS Inc. for assistance.

• Always add approximately one cup of water to each re-melt down to avoid lumpy paste.

WARNING: DO NOT PLUG IN UNIT UNTIL FILLED WITH 100% PURE ANTIFREEZE. MAINTAIN ANTIFREEZE

LEVEL APPROX. 1/2 FULL ACCORDING TO ANTIFREEZE INDICATOR.

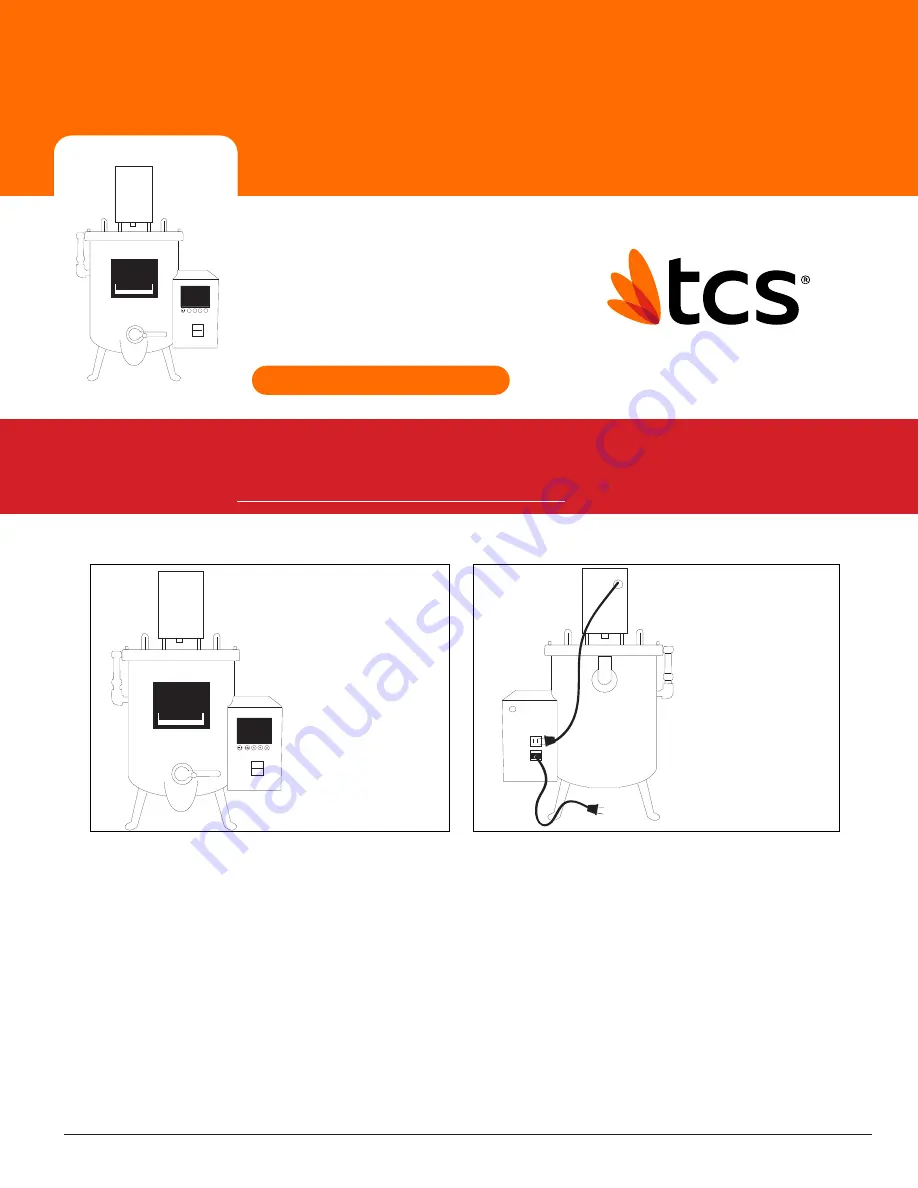

FRONT VIEW

A. Mixer motor

B. Handles

C. Mixer locking pins

D. Temperature controller

E. On/off button

F. Dispensing handle

G. Drip plate

H. Antifreeze indicator

BACK VIEW

I. Antifreeze intake pipe

J. Fuse

K. Mixer power cord 110V

L. Unit power plug

TCS Duplicating Unit - 2 gallon

Operating Instructions

please

read

manual

prior

to

use

1.

Get to Know Your Machine

SPECIFICATIONS

Capacity:

2 gallons

Weight:

20 lbs | 9 kilos

Dimensions:

Width 14-1/4’” | Height 21” | Tank diameter 10"

Dimensions:

110V

Model TC105