1

of 13

© 2014 TE Connectivity family of companies

All Rights Reserved

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product, and/or company names may be trademarks of their respective owners.

TOOLING ASSISTANCE CENTER 1-800-722-1111

PRODUCT INFORMATION 1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com.

Application Specification

114-13233

11 APR 14

Rev B

NOTE

All numerical values are in metric units [with U.S. customary units in brackets]. Dimensions are in millimeters [and inches].

Unless otherwise specified, dimensions have a tolerance of ±0.13 mm [±.005 in.] and angles have a tolerance of ±2°. Figures

and illustrations are for identification only and are not drawn to scale.

1.

INTRODUCTION

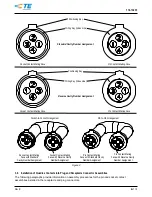

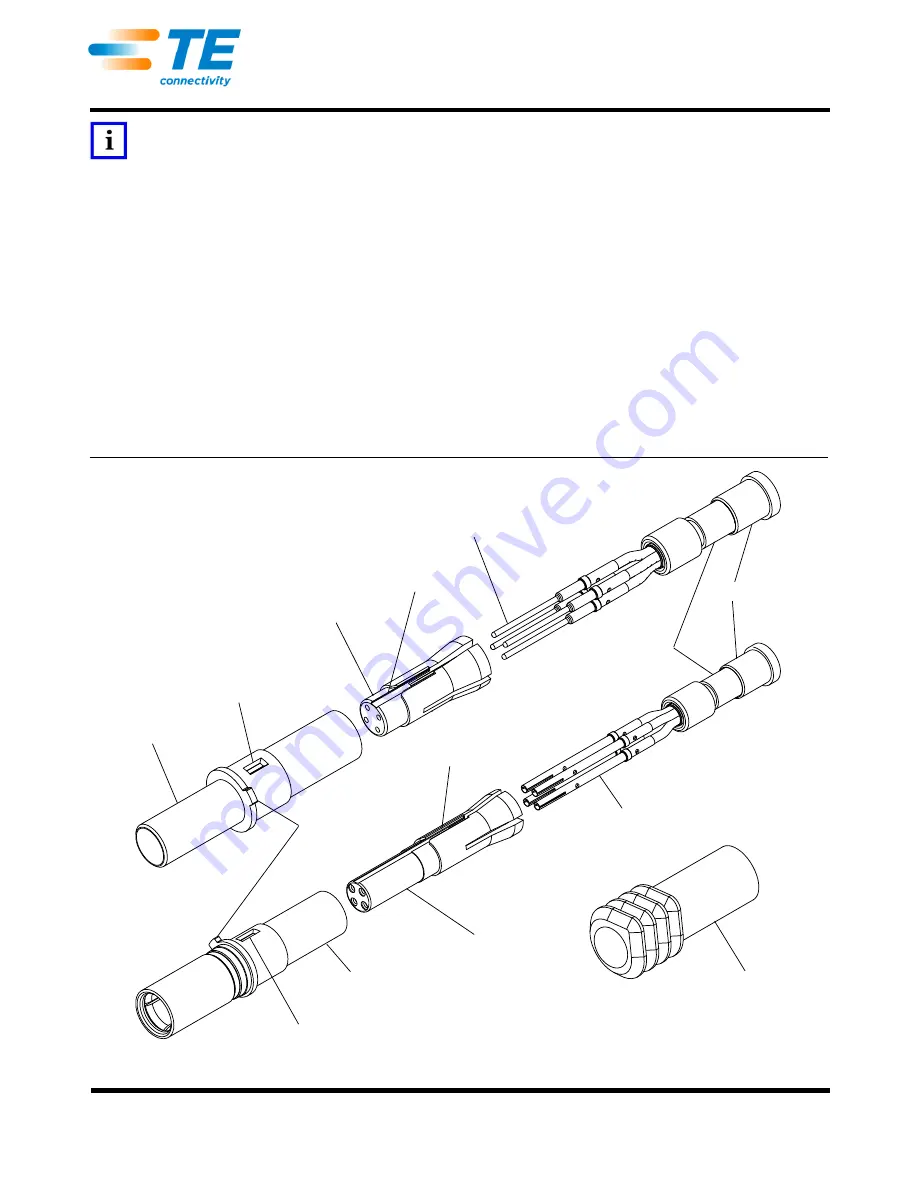

This specification covers the requirements for application of Quadrax DSub Connectors and Quadrax Contacts.

The Quadrax DSub Connectors consist of a four-position free hanging/ panel-mount plug, a right-angle printed

circuit (pc) board mount receptacle, and a free-hanging receptacle.

The Quadrax Pin and Socket Contacts shall be applied to appropriate Quadrax cables. The contact assembly

contains an outer shell, a one-piece dielectric, and four signal contacts. An inner crimp ferrule is included with

the cable applied contacts, and an optional sealing boot/plug is also available. These Quadrax Contacts may

also be used in other connector systems such as ARINC 600 Connectors, and MIL-DTL-38999 style

connectors. Contact TE Connectivity Product Engineering for specific application requirements for these other

product lines.

When corresponding with TE Personnel, use the terminology provided in this

s

pecification to facilitate inquiries

for information. Basic terms and features of this product are provided in Figure 1.

Figure 1

Quadrax DSub Connectors

and Quadrax Contacts

NOTE:

Figures and illustrations are for

reference only and are not drawn to scale.

Pin Shell

Pin Insert Dielectric

Slot

Pin Contact

Inner Ferrule

Cable Not

Included in Kit

Socket Insert

Dielectric

Positioning Key

Socket Contact

Slot

Wire Sealing

Boot (Optional)

Socket Shell

Wiring Key (Index Line)