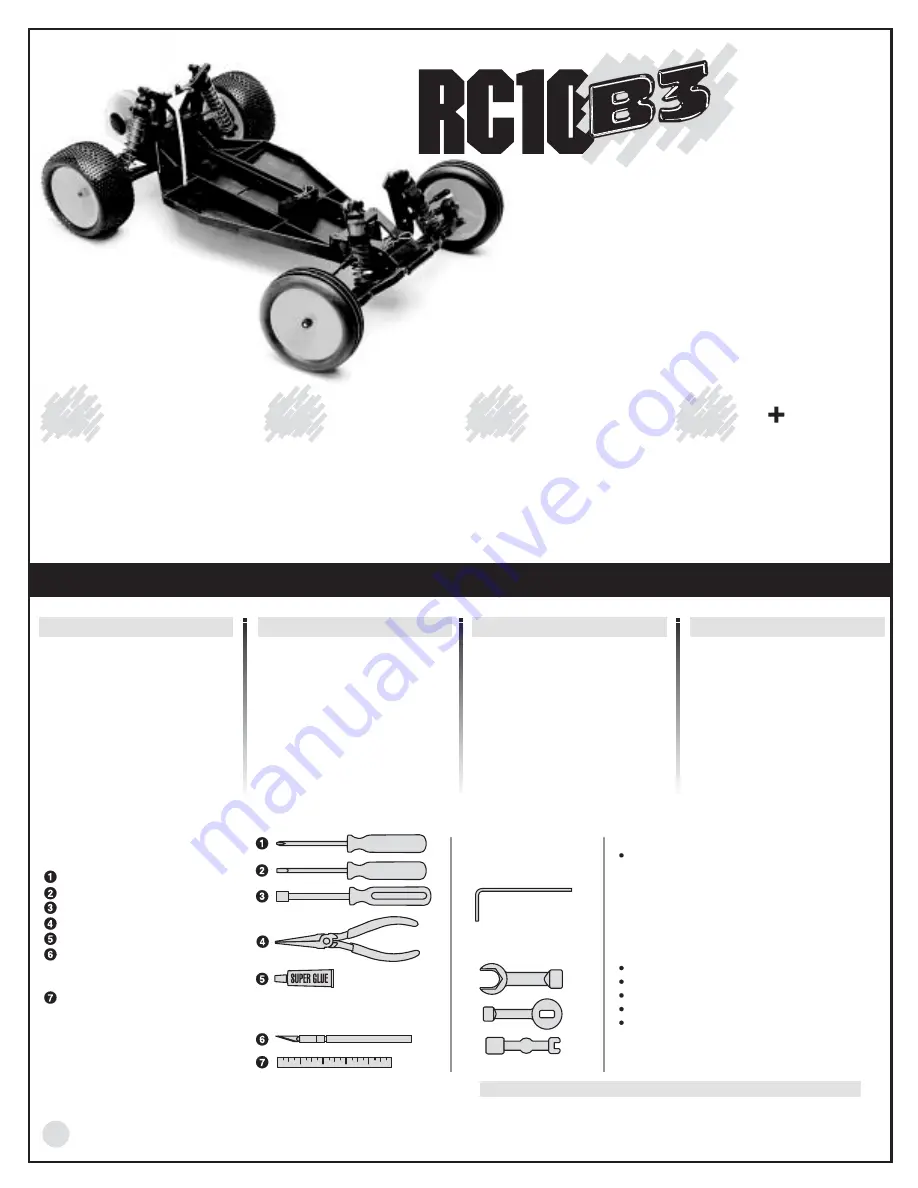

T E A M K I T

S P O R T K I T

B A S I C K I T

Shocks: Hard anodized,

PTFE

-

coated gray.

Rear Axles: MIP CVD's.

Also includes: Ball bearings

throughout.

Shocks: Gold shocks.

Rear Axles: Associated dogbones &

stub axles.

Also includes: Mechanical speed

control and motor. Bushings

throughout.

Shocks: Gold shocks.

Rear Axles: Associated dogbones &

stub axles.

Also includes: Bushings

throughout.

All kit versions include:

2.40:1 transmission for effortless power handling.

Molded composite chassis for better rigidity and Lexan B3 racing body.

Quadra-symmetric suspension for greater stability and handling.

Optimized front end geometry improves steerging and increases rigidity.

Adjustable battery placement for fine tuning of traction or steering.

2.2" one-piece front and rear wheels.

Pro-Line 4 Rib M2 front tires and Pro-Line "Holeshot" M2 rear tires.

F A C T O R Y T E A M

Shocks: Hard anodized,

PTFE

-

coated gray.

Rear Axles: MIP CVD's.

Also includes: Factory Team

parts, ball bearings throughout.

2

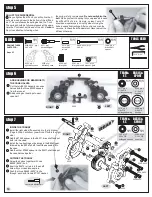

YOU WILL NEED THESE TOOLS

TO ASSEMBLE YOUR KIT

Phillips screwdriver #2.

1/8" flat head screwdriver.

5/16" driver or glow plug wrench.

Needlenose pliers.

Super glue (cyanoacrylic glue).

Hobby knife

WARNING! This knife

cuts plastic and fingers with equal

ease, so be careful.

Precision ruler.

WARNING! Always use hand and eye

protection with cyanoacrylic glue!

for the

B3 Basic+ kit #9003

R/C two channel surface

frequency radio system

with one servo.

Battery pack (6 cell).

Battery charger (we recommend

a peak detection charger).

Electronic speed control.

Pinion gear, 48 ptich. Teeth to be

determined by type and wind of

motor.

R E Q U I R E D E Q U I P M E N T T O R U N Y O U R K I T

for the

B3 Sport kit #9013

R/C two channel surface

frequency radio system

with two servos.

Battery pack (6 cell).

Battery charger (we recommend

a peak detection charger).

for the

B3 Team kit #9032

R/C two channel surface

frequency radio system

with one servo.

Battery pack (6 cell).

Battery charger (we recommend

a peak detection charger).

Electronic speed control.

R/C electric motor.

Pinion gear, 48 ptich. Teeth to be

determined by type and wind of

motor.

TOOLS SUPPLIED

Allen wrenches, .050",

1/16", 3/32", 5/64".

Molded tools (#6956):

for the

Factory Team kit #9043

R/C two channel surface

frequency radio system

with one servo.

Battery pack (6 cell).

Battery charger (we recommend

a peak detection charger).

Electronic speed control.

R/C electric motor.

Pinion gear, 48 ptich. Teeth to be

determined by type and wind of

motor.

HELPFUL TOOLS (NOT REQUIRED)

Allen drivers (straight Allen wrenches with hex

shaped handles) such as the following made by

Associated:

#6957

.050" Allen wrench

#6958 1/16"

Allen

wrench

#6959 5/64"

Allen

wrench

#6960 3/32"

Allen

wrench

#6961 2.5mm

Allen

wrench

Hand drill with 1/8" & 1/4" bits

Vernier calipers

Hobby scissors

Liquid dish soap

Nut drivers (screwdriver-handled hex socket

tools) such as the following from Associated:

#SP-86 3/16" nut driver

#SP-85 1/4" nut driver

WARNING!

Do not use a power screwdriver to install screws into nylon, plastic, or

composite materials. The fast rotation speed can heat up the screws being

installed. They can then break the molded parts or strip the threads during

installation.