5680/5700/5700XP

KIT NO. 9006309--5680, 9006310--5700/5700XP

Page 1 of 7

t

ec- H2O

Kit

9005074 Rev. 01 (07--09)

Tennant Company

Customer Service: (800) 553--8033 or (763) 513--2850

This kit includes the necessary parts to convert a standard model into an

ec- H2O

t

model.

INSTALLATION INSTRUCTIONS:

Installation Time: 5 Hours

Special Tools Required: Fish--Tape to route

ec-H2O

harness.

PREPARE MACHINE FOR KIT INSTALL:

1. Drain the solution tank and recovery tank.

2. Park the machine on a level surface. Lower the

scrub head and remove the key.

FOR SAFETY: Before installing kit, disconnect

battery cables.

3. Remove the front shroud.

4. Disconnect the actuator at the scrub head.

5. Remove the actuator roller guide brackets and

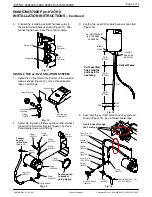

discard (Figure 1).

Remove the

two Actuator

Roller Guide

Brackets

Fig. 1

6. Install the

ec--H2O

module bracket, pump bracket

and clamps as shown (Figure 2).

ec--H2O

Pump

Bracket

[1002603]

M8x1.25x20

Screw (4) [12273]

M8x1.25x16

Screw [15675]

Clamp (2) [53466]

Clamp [69234]

Flat Washer (5) [01685]

ec--H2O

Module

Bracket [1044803]

NOTE:

Do not tighten the top screws w/ clamps at

this time. You will need to open the clamps later to

route

ec--H2O

wire harness through clamps.

Fig. 2

INSTALL

ec- H2O

WIRE HARNESS:

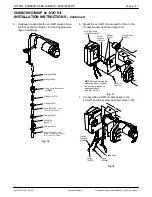

1. Using a Fish--Tape, route the

ec--H2O

wire

harness through the harness channel along side

the machine’s main wire harness (Figure 3). Pull

the harness from the front of the machine to the

back (Figure 3).

p/n 1044831 -- 5680

ec--H2O

Wire Harness

p/n 1044833 or 1055478 -- 5700

ec--H2O

Wire

Harness

Harness

Channel

NOTE:

If installing

the 5700

ec--H2O

kit,

cut off the fuse

connector to allow

clearance to route

harness. After

completing step 3

(Fig 5a), reconnect

wire with an

insulated16G

butt--splice

connector.

(5680

harness

shown)

Fuse

Connector

Cut Here

Fish--Tape

Insert

harness

end here

Route this

end of

harness

(5700 harness)

Fig. 3

2. Open the control console to access the internal

wiring (Figure 4). Two screws secure console.

Fig. 4