Builder, Subcontractor or Supplier:

Please forward these instructions to the homeowner.

The application performance standards for these products may be governed by

the International Residential Code, International Building Code and other state

and jurisdictional requirements. Copies of performance ratings are available

on our website at

www.thermatru.com

.

Installation Instructions for

Pre-hung Door Systems

These installation instructions are designed to assist door installers who have

an understanding of carpentry principles, and know how to properly and

safely use power tools. The purpose of these instructions is to illustrate how

to install a Therma-Tru door system using methods and materials that help

eliminate water related leaks. If the directions are closely followed, the door

system will have a long useful life with good resistance to rain related water

intrusion problems.

These methods are “tried and true” They are used widely by builders and

remodelers who are serious about managing and keeping water outside the

home. Rather than eliminate any steps that may be unclear to you, please call

1-800-THERMATRU and ask for clarification. If you remain unclear, please

seek more professional assistance with the installation.

Different parts of the country have different code requirements, which may

not be covered in these instructions. The installer is responsible for insuring

the installation complies with local codes. If you have unique code

requirements that do not appear please contact 1-800-THERMATRU.

Required Tools & Materials:

2 & 6 foot Levels, Hammer, Putty Knives

(firm & flexible), Framing Square, Caulking Gun, Sturdy Ladder, Shims,

Tape Measure, High Quality Elastomeric or Polyurethane Sealant, Screw

Gun/Drill -1/8 inch Drill Bit, Razor Knife, #2 & #3 Philips Bit, Stapler,

Insulating Material, Eye Protection, Water Resistive Barrier, Flashing

Material, #8 x 2-1/2 inch Exterior Grade Screws, & Optional Sill Pan.

Read all instructions before starting.

Therma-Tru Recommended Best Practices

Use Water Resistive Barrier and Flexible Flashing:

We recommend the use of a Water Resistive Barrier

(WRB) applied to the exterior sheathing (OSB or

other) and the use of an adhesive or flexible flashing

product to seal around the opening. The WRB should

be cut in the opening (follow manufacturer’s

guidelines) with the head of the flap taped up, to be

sealed later in Step 11. The flashing should be applied

in an overlapping manner as shown, always working

from the bottom up (follow manufacturer’s

guidelines).

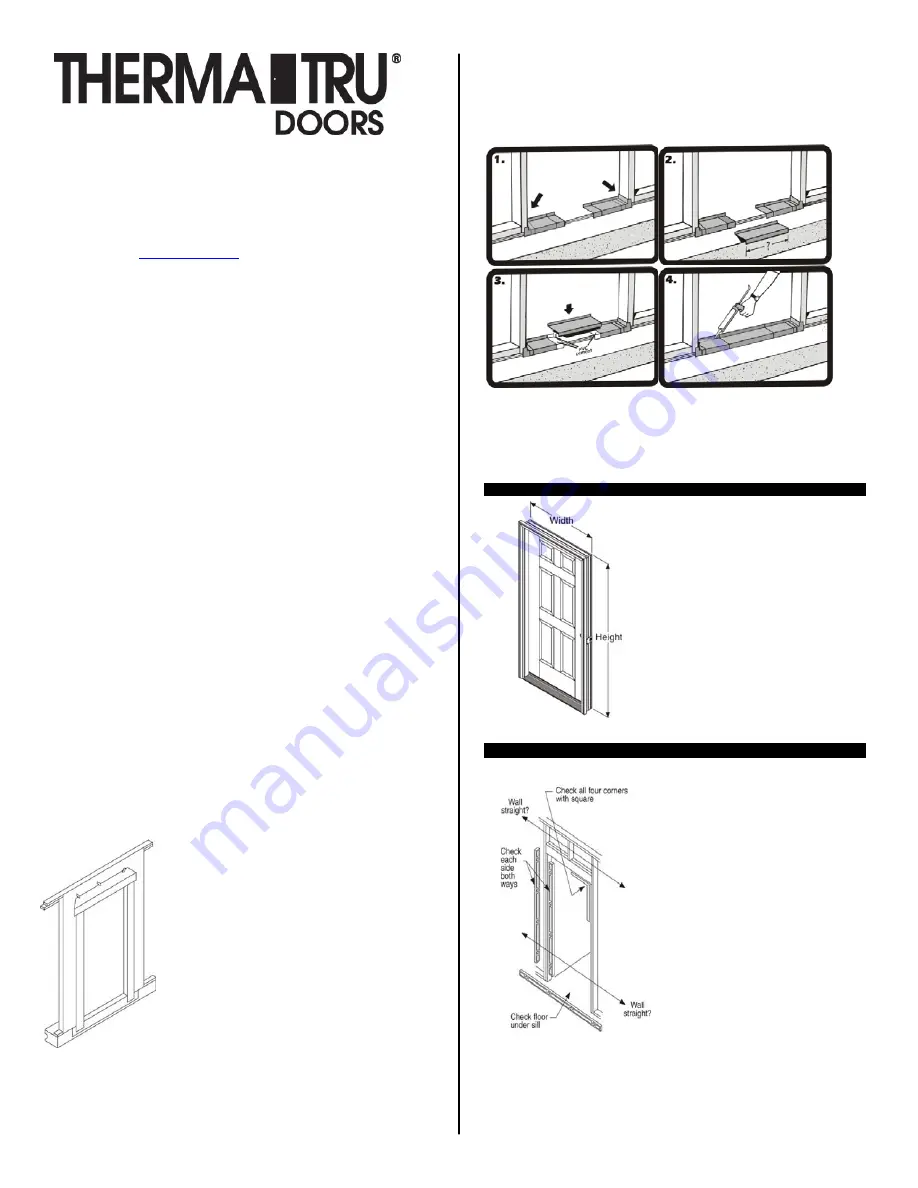

Use a Sill Pan:

We recommend you first “dry fit” the sill pan in the opening,

following the instructions furnished with the sill pan. Place the right and left

sill pan ends tight against the sides of the opening. Check the center section

for proper length and if necessary, cut with a hack saw or tin snips. Be sure to

allow 2 inches of overlap at the joints.

Note:

Use only the PVC cement provided in the sill pan kit to glue the pieces

together. The sill pan must be sealed to the sub-floor using an Elastomeric or

Polyurethane sealant, but do not apply sealant to the bottom of the sill when

using a sill pan.

Step 1: Check Door Unit.

Check width and height.

Measure size of frame (width and height), not

brickmould.

Remove cleats and packaging, but keep door

fastened closed with transport clip. Do Not

remove the transport clip until instructed to do

so later in Step 7.

Step 2: Check and Prepare Opening.

Is the opening the correct size for the

door unit? Check it against the door

frame size now, before installation. The

opening should be frame height plus 1/2

inch, and frame width plus 1/2 inch to

3/4 inch.

Fix any problems now.

Are the framing and walls

PLUMB

? Use

a 6 foot level and check both sides of the

opening, both ways (front to back and

right to left).

Fix any problems now.

Is the sub floor level and solid?

Provide

a flat, level, clean weight bearing

surface so the sill pan or sill can be

properly caulked and sealed to the

opening. Scrape sand or fill as required.

Note:

If additional floor covering clearance is required, attach the shim board

to the sub floor. Be sure to caulk well under the shim board.

Is the opening square? Check all corners with a framing square. Double check

by comparing diagonal measurements.

Fix any problems now.