SCION tC

2008-

ILLUMINATED DOOR SILLS

Preparation

Page 1 of 17 pages

Issue: C 06/13/07

Part Number: PTS21-21070

NOTE:

Part number of this accessory may not be

the same as the part number shown.

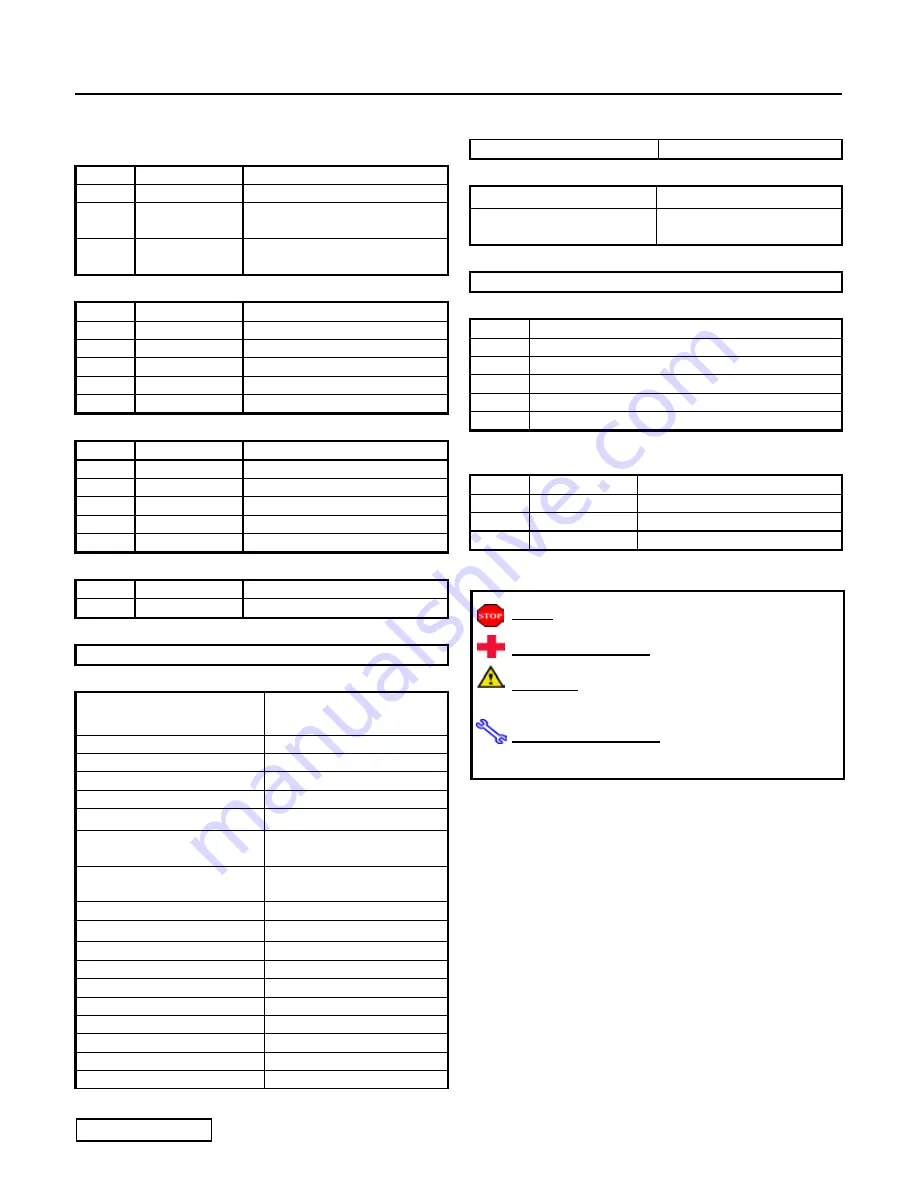

Kit Contents

Item #

Quantity Reqd. Description

1

2

Hardware Kit w/ power harness

2

1

Front Left Illuminated Door Sill

Protector

3

1

Front Right Illuminated Door

Sill Protector

Hardware Kit Contents (LH)

Item #

Quantity Reqd. Description

1

1

Power Harness with Fuse

2

2

Foam Pad (38.1 x 38.1 x 4.75)

3

1

Foam Pad (63.5 x 38.1 x 1.57)

4

12

Wire Ties

6 2

T-taps

Hardware Kit Contents (RH)

Item #

Quantity Reqd. Description

1 1

Power

Harness

2

2

Foam Pad (38.1 x 38.1 x 4.75)

3

1

Foam Pad (63.5 x 38.1 x 1.57)

4

27

Wire Ties

6 1

T-taps

Additional Items Required For Installation

Item #

Quantity Reqd. Description

Conflicts

None

Recommended Tools

Personal & Vehicle

Protection

Notes

Safety Glasses

Safety Gloves

Optional

Vehicle Protection

Blankets, Part Boxes,

Protective film

PPO only, Wrap Guard

Special Tools

Notes

Non-intrusive temperature

probe

For measuring door sill

temperature if necessary

Blow Drier

For cold temperature

installations.

Installation Tools

Notes

Nylon Panel Removal Tool

Screwdriver Phillips

head

#2

Ratchet

Extension 6

in

Socket

10 mm (deep socket)

Torque Wrench

36 lbf-in

Non-scratch wiping cloth

3M Micro-fiber

Pliers

Wire Cutters

Special Chemicals

Notes

All Purpose Cleaner

mild water based, solvent

free all purpose cleaner.

General Applicability

2008 SCION - tC

Recommended Sequence of Application

Item #

Accessory

1

V5 Security –

2

Illuminated Door Sills

3 Audio

4 Satellite

Radio

5 Interior

Light

Kit

Vehicle Service Parts

(may be required for reassembly)

Item #

Quantity Reqd. Description

Legend

STOP:

Damage to the vehicle may occur. Do not

proceed until process has been complied with.

OPERATOR SAFETY:

Use caution to avoid risk of

injury.

CAUTION:

A process that must be carefully observed

in order to reduce the risk of damage to the

accessory/vehicle and to ensure a quality installation.

TOOLS & EQUIPMENT:

Used in Figures calls out the

specific tools and equipment recommended for this

process.