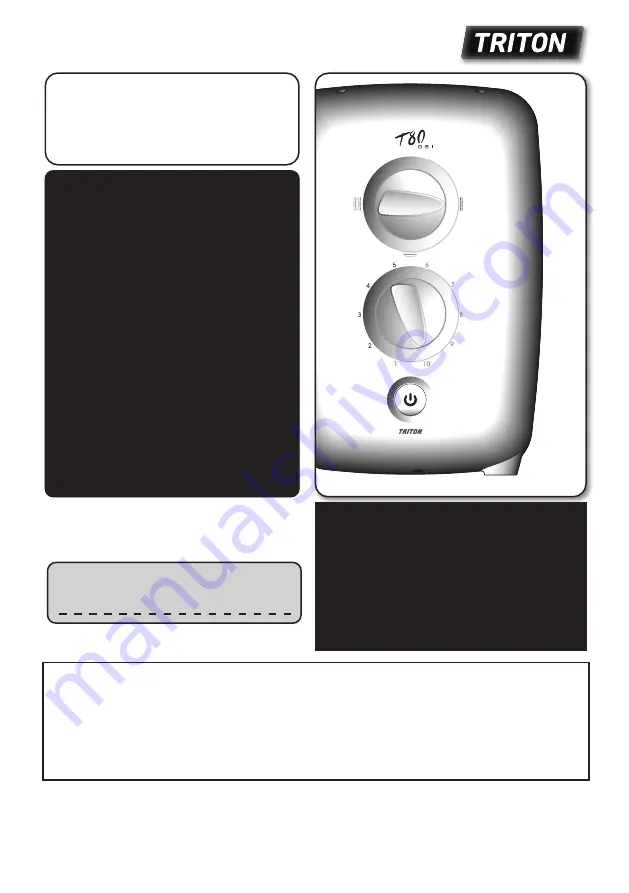

2181057L

- September 2020

T 8 0 G S I

electric shower

FOR YOUR SERVICE REFERENCE

NOTE DOWN THE PRODUCT CODE BELOW

(FROM THE FRONT OR TOP OF THE BOX)

ALTERNATIVELY REGISTER BY TEL: 024 7637 8321

INSTALLATION AND OPERATING INSTRUCTIONS

Please read this book thoroughly and familiarise yourself with all instructions before commencing

installation and keep it for future reference.

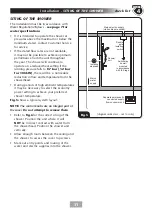

The shower installation

MUST

be carried out by a suitably qualified person,

in the sequence of

this instruction book.

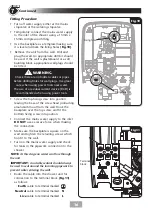

IMPORTANT SAFETY ADVICE

The shower unit

MUST BE

switched off at the

isolating switch when not in use. This is a

safety procedure recommended for all

electrical appliances.

The showerhead and hose supplied with this

product are a safety critical part of your shower.

Failure to use genuine Triton parts may cause

injury and invalidate your guarantee.

THIS OFFER IS NOT VALID OUTSIDE THE UK

REGISTER ONLINE

ENTER A PRIZE DRAW

WIN

£100

LOVE2SHOP VOUCHERS

VISIT OUR WEBSITE TODAY

TRITONSHOWERS.CO.UK/REGISTER

PRODUCT REGISTRATION IS ONLY AVAILABLE

TO UNITS PURCHASED & INSTALLED IN THE UK