AEV350, MEV350

TWO PART VALVE HOUSING,

AUTO AND MANUAL EXPULSION

Installation and User Guide

32210-001 REV A

Trulife

www.trulife.com

Page 1 of 4

INTRODUCTION

The AEV350 and the MEV350 valves are intended for transfemoral prosthetic suction sockets. Both utilize the same two-part valve

housing, which is ideal for use with flexible thermoplastic socket materials.

The AEV350 valve insert has automatic air expulsion function and manual push button to release suction.

The MEV350 valve has a push button used to manually expel air and to release suction.

Both type valve inserts are removable to allow use of a pull-sock for donning the socket.

Both are furnished with valve key and necessary components to form the socket to accept the two-part valve housing.

Product Code

Description

AEV350

AUTO EXPULSION VALVE WITH TWO-PART HOUSING

MEV350

MANUAL EXPULSION VALVE WITH TWO PART HOUSING

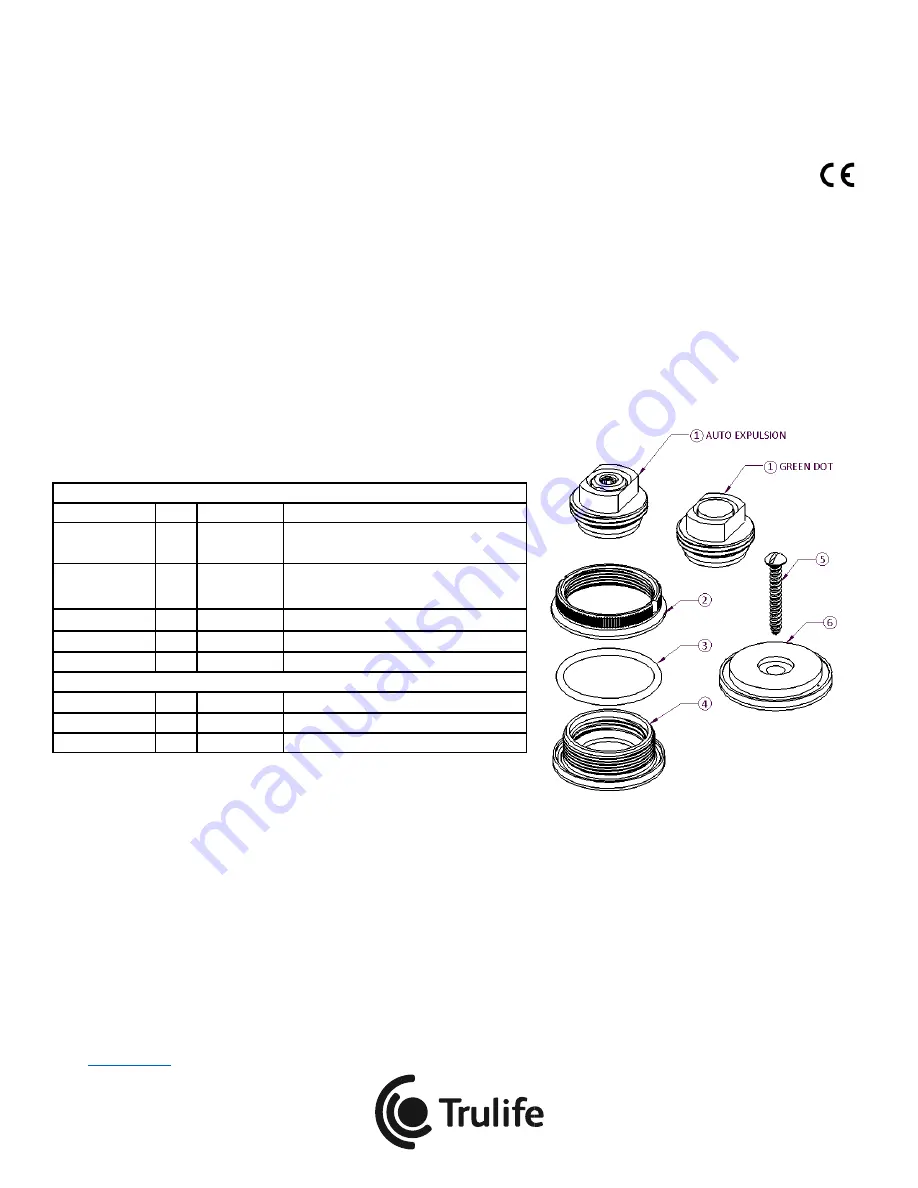

PRODUCT CONTENTS:

ITEM

QTY

PART #

DESCRIPTION

1

(AEV350)

1

32201-001

AUTO EXPULSION VALVE INSERT

ASSEMBLY

1

(MEV350)

1

32213-001

MANUAL EXPULSION VALVE INSERT

ASSEMBLY

2

1

32207-002

SOCKET OUTER HOUSING

3

1

32212-001

O-RING, SIZE -125

4

1

32208-001

SOCKET INNER HOUSING

FABRICATION / ADDITIONALCOMPONENTS :

5

1

24437-001

SCREW, SIZE #8 X 1.25" LONG

6

1

32209-001

FORMING TOOL

7

1

19774-001

VALVE KEY ASSEMBLY (NOT SHOWN)

INSTALLATION AND USE

Recommended installation and use procedures must be followed for maximum safety and service life.

Socket Preparation:

1.

Determine valve location on the positive model. Flatten the region so the forming tool is flush. Mark the center hole

location of the forming tool.

2.

Drill a Ø3.2mm (Ø1/8”) pilot hole for the supplied screw.

3.

Drill a vacuum channel hole 12mm (1/2”) adjacent to the pilot hole with a long drill. This hole must extend through the

model so that vacuum will draw at the forming tool site.

4.

Secure the forming tool to the model with the supplied screw, and positioning it so that one of the small holes in the

forming tool is over the vacuum channel hole.

5.

Vacuum form the thermoplastic socket. Manually apply the necessary external pressure around the forming tool to help

guide the softened thermoplastic to fully form around the tool.