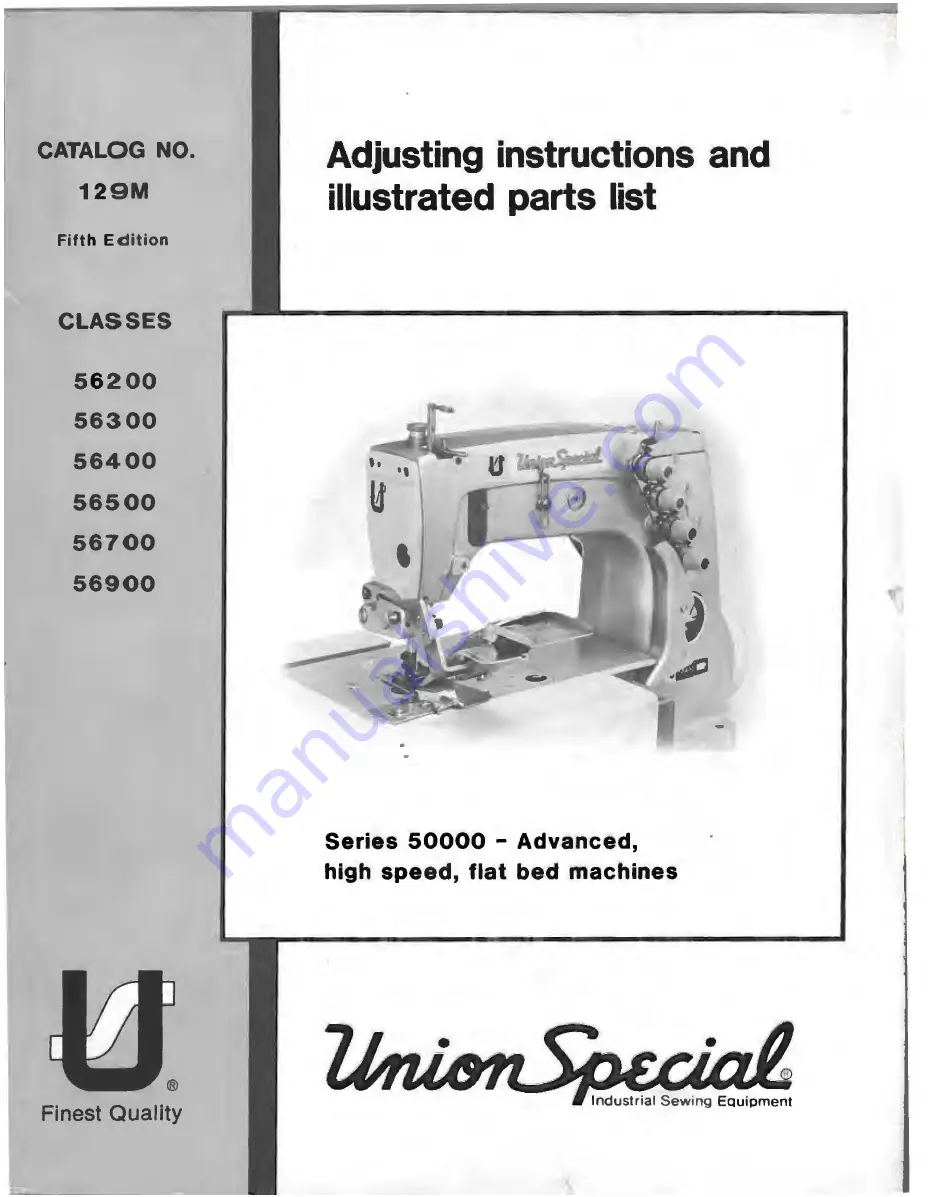

Summary of Contents for 56200

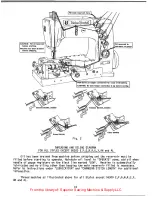

Page 24: ...From the library of Superior Sewing Machine Supply LLC 56 50 i ...

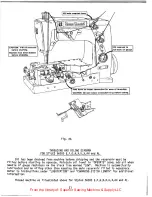

Page 26: ...From the library of Superior Sewing Machine Supply LLC 24 26 18 201 8 G ...

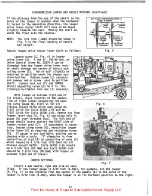

Page 34: ...From the library of Superior Sewing Machine Supply LLC 34 ...

Page 36: ...From the library of Superior Sewing Machine Supply LLC r Qm_ 2r IJ 19 L_ 36 ...

Page 38: ...From the library of Superior Sewing Machine Supply LLC 5 I I 24 L_ t 28 31 2 9 30 38 ...

Page 40: ...From the library of Superior Sewing Machine Supply LLC li 2e 1 Iilr1l I 1 29 _ 3B 40 ...

Page 42: ...From the library of Superior Sewing Machine Supply LLC 11 2 25 2 4 40 42 ...

Page 44: ...From the library of Superior Sewing Machine Supply LLC A 2 23 44 ...

Page 46: ...From the library of Superior Sewing Machine Supply LLC 46 ...

Page 48: ...From the library of Superior Sewing Machine Supply LLC 12 48 ...

Page 50: ...From the library of Superior Sewing Machine Supply LLC 34 50 ...

Page 52: ...From the library of Superior Sewing Machine Supply LLC 52 ...

Page 54: ...From the library of Superior Sewing Machine Supply LLC 18 54 ...

Page 56: ...From the library of Superior Sewing Machine Supply LLC 56 ...

Page 58: ...From the library of Superior Sewing Machine Supply LLC J 58 ...

Page 60: ...From the library of Superior Sewing Machine Supply LLC 60 ...

Page 62: ...From the library of Superior Sewing Machine Supply LLC 62 ...

Page 64: ...From the library of Superior Sewing Machine Supply LLC 64 ...

Page 66: ...From the library of Superior Sewing Machine Supply LLC 66 I I ...

Page 68: ...From the library of Superior Sewing Machine Supply LLC 3 68 ...

Page 70: ...From the library of Superior Sewing Machine Supply LLC 20 8 70 ...