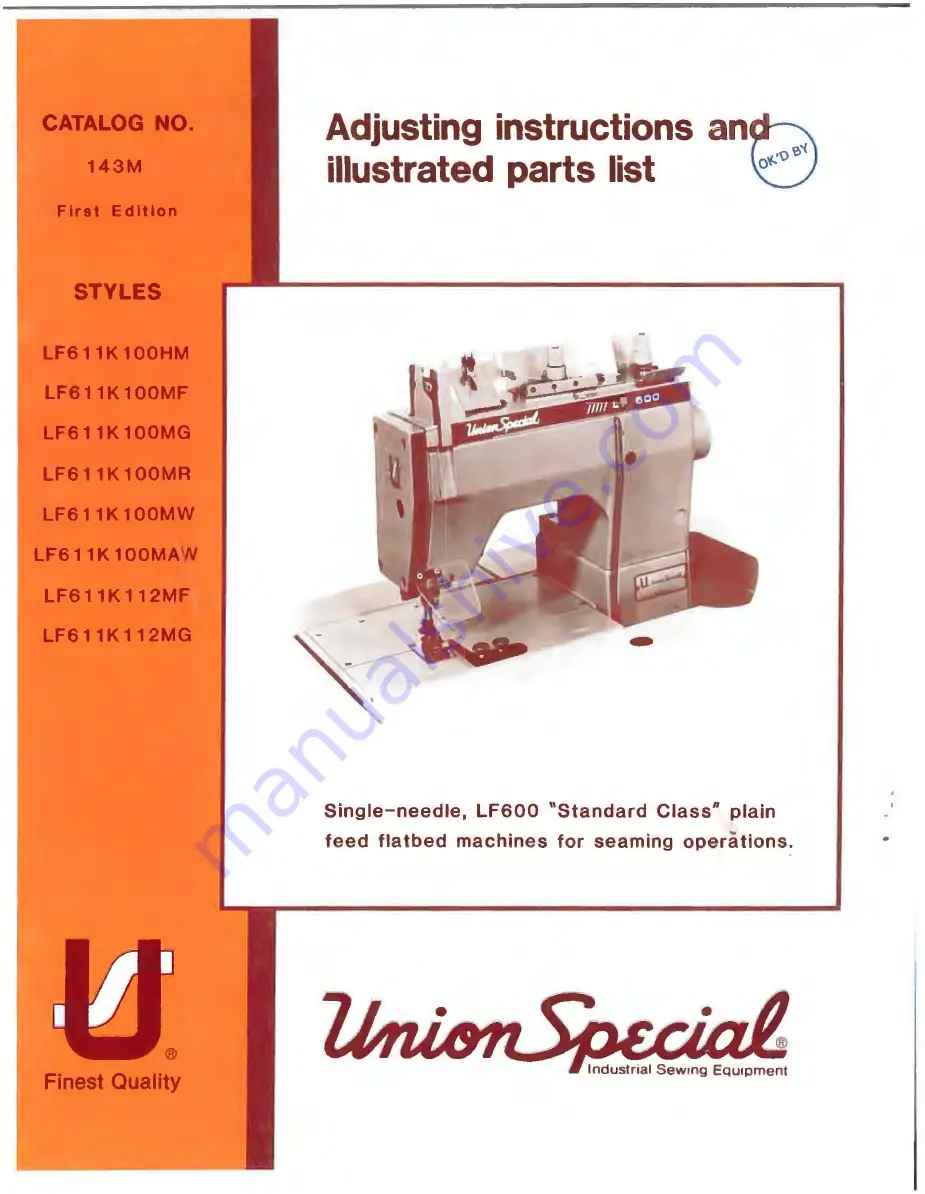

Summary of Contents for LF611K 100HM

Page 24: ...From the library of Superior Sewing Machine Supply LLC 24 ...

Page 26: ...From the library of Superior Sewing Machine Supply LLC 15 21 26 43 30 P104 42 26 ...

Page 30: ...From the library of Superior Sewing Machine Supply LLC 30 ...

Page 32: ...From the library of Superior Sewing Machine Supply LLC 6 16 22 t5 40 P107 32 ...

Page 34: ...From the library of Superior Sewing Machine Supply LLC 9 5 48 42 41 39 33 34 P108 34 ...

Page 36: ...From the library of Superior Sewing Machine Supply LLC 36 ...

Page 38: ...From the library of Superior Sewing Machine Supply LLC 11 10 9 r 2 3 p 11 0 38 ...

Page 40: ...From the library of Superior Sewing Machine Supply LLC 7 8 P 111 40 ...

Page 42: ...From the library of Superior Sewing Machine Supply LLC p 1 1 2 42 LF611K100HM STYLE 24 33 43 ...

Page 44: ...From the library of Superior Sewing Machine Supply LLC 4 50 7 _______ _ p 113 44 ...

Page 46: ...From the library of Superior Sewing Machine Supply LLC 31 p 1 14 46 ...

Page 55: ...From the library of Superior Sewing Machine Supply LLC Notes _ ________________ _ _ ...