Important

Read these instructions carefully before installing, operating,

servicing or repairing this tool. Keep these instructions in a safe

accessible place.

Operator Instructions

Includes - Foreseen Use, Work Stations, Putting Into Service, Operating,

Dismantling, Assembly and Safety Rules

Manufacturer/Supplier

Product Type

RPM

Cycles Per Min

Model No/Nos

Serial No

Product Nett Weight

lbs

Kg

Recommended Use Of

Balancer Or Support

Recommended Hose Bore

Size - Minimum

Recommended Max.

Hose Length

Ins

M/M

Ft

M

No

Page No 1

Heavy Duty Dual Action

Sanders-150mm (6” Dia Pad)

UT8709

UT8709-DC (Dust

Collecting)

2.9

1.3

3/8

10

30

10

9,000

Universal Air Tool Company Limited

Unit 8

Lane End Industrial Park

High Wycombe

Bucks

HP14 3BY

Work Stations

The tool should only be used as a

hand held hand operated tool. It is

always recommended that the tool is

used when standing on a solid floor.

It can be used in other positions but

before any such use the operator

must be in a secure position having a

firm grip and footing and be aware of

the safety rules to be obeyed when

using the sander.

Foreseen Use of Tool

This tool is designed for the purpose of cleaning or sanding of a

variety of materials typically metal, wood, plastic materials, etc. The

dual rotary orbital action reduces the amount of abrasive grinding

marks and hence is primarily a finishing sanding tool. It can be used

with a variety of grades of 150 mm (6” diameter) abrasive discs

which, according to pad fitted to the tool, can be self adhesive or

Velcro attached. If fitted to the dust collecting system this should

always be used. The system may be integral or required to be fixed

to an external vacuum source.

The machine fitted with dust collection should not be used with water.

If use with water is required, water can act as a dust suppressor and

the dust collector would not be required.

Do not use the tool for any other purpose to that for which it has

been designed and use only abrasive discs as described.

Do not modify the tool for any other use or for its use as a sander

without first consulting the manufacturer or his authorised distributor.

Putting Into Service

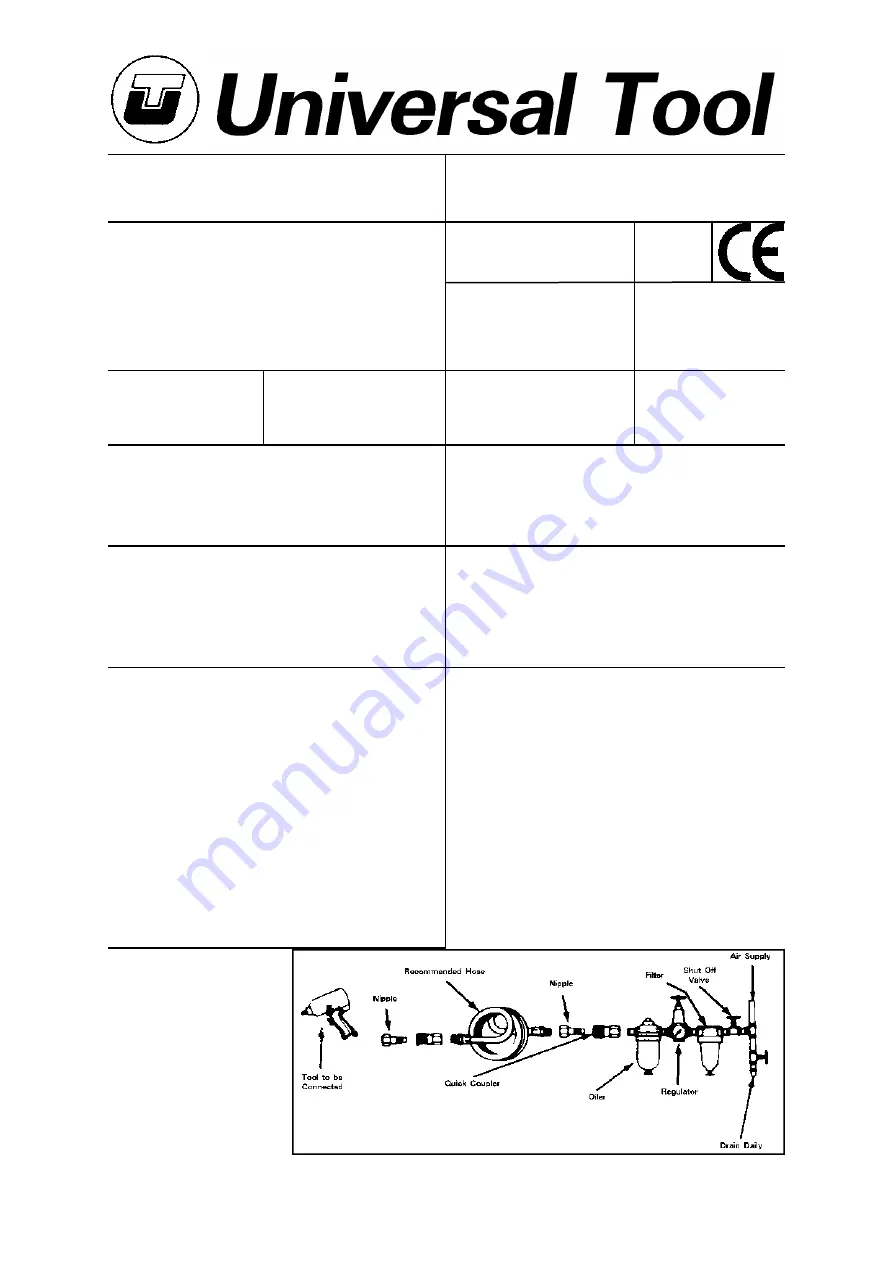

Air Supply

Use a clean lubricated air supply that will give a measured air pressure

at the tool of 90 p.s.i./6.3 bar when the tool is running with the

trigger/lever fully depressed. Use recommended hose size and

length. It is recommended that the tool is connected to the air supply

as shown in figure 1. Do not connect the tool to the air line system

without incorporating an easy to reach and operate air shut off valve.

The air supply should be lubricated. It is strongly recommended that

an air filter, regulator, lubricator (FRL) is used as shown in Figure 1

as this will supply clean, lubricated air at the correct pressure to the

tool. Details of such equipment can be obtained from your supplier.

If such equipment is not used then the tool should be lubricated by

shutting off the air supply to the tool, depressurising the line by

pressing the trigger on the tool. Disconnect the air line and pour into

the intake bushing a teaspoonful (5ml) of a suitable pneumatic motor

lubricating oil preferably incorporating a rust inhibitor. Reconnect tool

Tel No

Fax No

(01494) 883300

(01494) 883237

Noise Level

Sound Pressure Level 80.0 dB(A)

Test Method

Tested in accordance with Pneurop

test code PN8NTC1 and ISO Standard 3744

Vibration Level

Test Method

Tested in accordance with ISO

standards 8662 Parts 1 & 8

Less than 2.5

Metres / Sec²

Air Pressure

Recommended Working

6.3

bar

90

PSI

Recommended Minimum

n/a

bar

n/a

PSI

Maximum

7.0

bar

100

PSI

Personal Safety Equipment

Use - Safety Glasses

Yes

Use - Safety Gloves

Use - Safety Boots

Use - Breathing Masks

Yes

Use - Ear Protectors