©Vantage, 9/2/2015 / IS-00709-B

Commercial Power Enclosure Solutions — MODEL: LCAP44A

page 1 of 2

POE SWITCH

COM-POE-SWITCH

EMR. SWITCH

VA-RRU-1-12OV

(277V)

EMR. SWITCH

VA-EPC-DFS-12OV

(277V)

Please see install sheets for

emergency switch applications.

I N S T A L L A T I O N

V A N T A G E C O N T R O L S . C O M

V A N T A G E I N S T A L L G U I D E S

1061 South 800 East, Orem, Utah 84097

●

Telephone: 801 229-2800

●

Fax: 801 224-0355

Commercial Power Enclosure Solutions — MODEL: LCAP44A

Overview

Vantage’s

LCAP Series Commercial Enclosures

ship with pre-

configured modular solutions for commercial, architectural load

dimming and switching. The pre-configured designs save time in

Design Center and installing.

The UL listed LCAP44A panels are adaptable to spaces that have

mixed 0-10V, and PWM loads and HV relay loads via Vantage’s

LVOS-0-10-PWM station. LCAP44A connects to any controller

over the local network for easy connection and scalability.

Solution 1 – Parent-level Enclosure Models

Main Enclosure

Description

LCAP44 44”

Architectural

Enclosure

Optional Parts

Description

VA-RRU-1-120V

Emergency Shunt Relay - 120V

VA-RRU-1-277V

Emergency Shunt Relay - 277V

VA-EPC-DFS-120V Emergency

Lighting Surface Mount Switch 120V

VA-EPC-DFS-277V Emergency

Lighting Surface Mount Switch 277V

Specifications

LCAP44A

Specifications

Cabinet Dimensions

HWD

44.5” x 24” x 4.575” / 113cm x 61cm x 11.6cm

Door Dimensions HWD

44.5” x 24” x 0.75” / 113cm x 61cm x 2cm

Panel Insert HWD

42” x 21” x 4.175” / 106.7cm x 53.3cm x 10.6cm

Weight Enclosure

41 lbs / 18.6 kg

Weight Door

20.7 lbs / 9.39 kg

Weight Panel Insert

23 lbs / 10.43 kg

Number of LVOS-0-10-PWM

*

stations

Up to 6

Analog, 0-10DC/LV — Max. Outputs

Up to 24

PWM, LV — Max. Outputs

Up to 24

HV Relay 120-277 VAC — Max. Outputs

Up to 24

Line Feeds (breakers) required

1 and Up

Enclosure Finish

Galvanized Steel

Door Finish

Black - Powder Coated

Cover

vented, hinged

HV Wire

copper wire, min of 80°C/176°F insulation

Ventilation

maintained 36” front clearance

Ambient Operating Temp.

0-40°C / 32-104°F

Ambient Operating Humidity

5-95% non-condensing

UL, CUL, and CE listed

yes

* See these install sheets for important information:

Low Voltage Output Station Lighting_LVOS-0-10-PWM-1

LCAP Enclosure Designs

LCAP Series Enclosure Facts.

•

Enclosures must be populated from

left to right

and

top down

.

o

Blank positions cannot be left between lighting modules in

Design Center setup.

•

Enclosures are pre-configured and wired (to the extent

possible) using specific combinations of the following

components. Installed components are dependent on the

enclosure design.

o

Components using high voltage wiring.

Mixed high voltage wiring.

o

Components using low voltage control signal wiring.

o

Components using low voltage communication wiring.

o

Components using high voltage and low voltage

connections made inside the enclosure.

•

The enclosure uses built-in barriers to separate high and low

voltage wiring.

o

Some designs include the barrier while other designs

require the barrier be added by the designer.

o

High voltage barriers may be installed between

120V/240V/277V load modules.

•

LCAP44A Enclosures only contain LVOS-0-10-PWM stations.

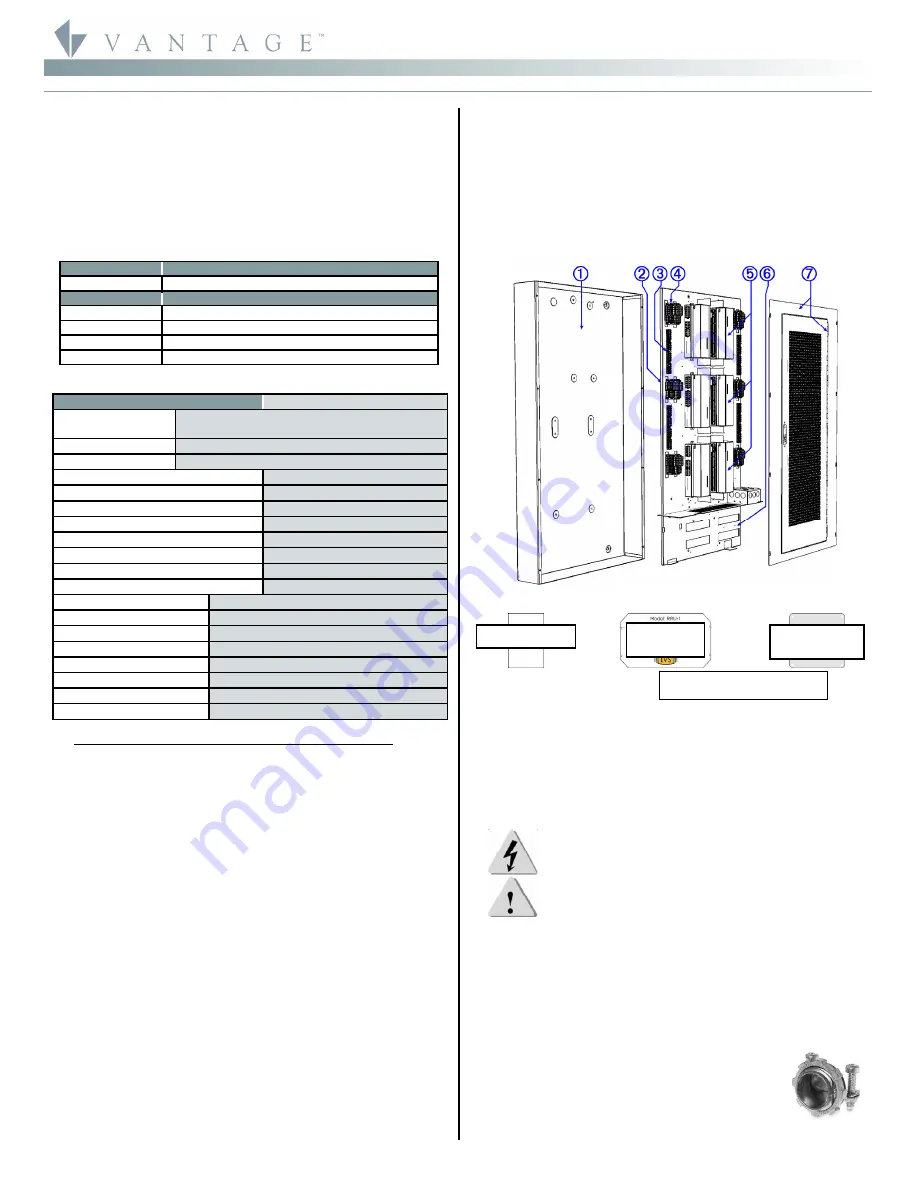

Enclosure Features / Parts

1.

Enclosure can.

2.

Panel Insert

3.

Ground terminals.

4.

Wiring terminal blocks (see close-up next page).

a.

Internal side pre-wired.

b.

External side wired in field.

5.

Up to 6, LVOS-0-10-PWM stations.

6.

LV section.

7.

Enclosure cover with hinged/vented door allowing easy access

when servicing and proper ventilation for convection cooling

process.

LCAP44A Panel Optional Construction Parts

Installation / Enclosure Mounting Instructions

Installation of Vantage LCAP products should be performed or

supervised by the Vantage factory and/or a

Certified Vantage

Installer.

Installation and maintenance of high voltage devices

should only be performed by

licensed, qualified,

and

competent

personnel having appropriate training and experience.

CAUTION:

Turn Breakers OFF and Check that no Power is ON at

the AC Terminal Boards when working in the

enclosure or working on lighting fixtures connected

to the Module’s Loads, etc. Do not allow trimmed wire

cuttings to fall into enclosure components as they

may cause damage when power is restored. Damage

from this type of short will

void

the warranty.

•

Do not mount enclosures in attics, garages, or crawlspaces,

unless room is properly conditioned to conform to ambient

room temperature and humidity requirements.

•

Mount enclosure a minimum of 18” from ceiling or floor.

•

National Electrical Code requires a minimum frontal clearance

of 36” for the enclosure.

•

Use screws provide for mounting.

General Wiring

Drill proper size holes in can for running wires in

and out of the enclosure. Separate high and low

voltage wire run channels.

All wire runs in and out

of the enclosure should be

secured

using

2-screw

connectors

or equivalent as shown at the right

.

Proper conduit or equivalent wire channels should

be used according to local codes and regulations.