Summary of Contents for VHR 04

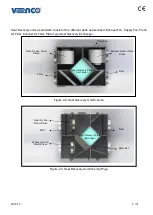

Page 8: ...2019 10 8 31 Table 3 2 Dimensions for VHR and VHR EC Models ...

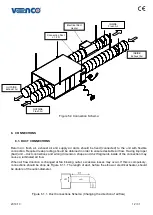

Page 23: ...2019 10 23 31 17 APPENDIX 17 1 APPENDIX 1 Standard Controller SEC Electrical Wiring Diagram ...

Page 24: ...2019 10 24 31 17 2 APPENDIX 2 Functional Controller FEC AC FAN Electrical Wiring Diagram ...

Page 25: ...2019 10 25 31 17 3 APPENDIX 3 Functional Controller FEC EC FAN Electrical Wiring Diagram ...