Quality does it.

ION/ PARTS CLEANER

No. IPC40-E

Application

This product is used to remove fine powder and dust attracted by static electricity and to remove static

electricity from parts that are negatively affected by static electricity.

A powerful air blower in an ionized space blows off the debris. The blown off debris is forcefully

collected by a dust collector.

Table of Contents

Instruction Manual

■

For Your Safety ································ P.2

■

Product Overview ···························· P.6

■

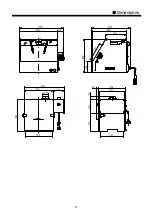

Dimensions ······································ P.9

■

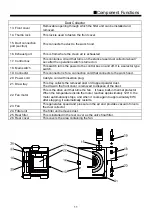

Component Functions ····················· P.10

■

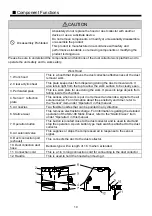

Installation ······································· P.13

■

Operation ········································· P.19

■

Maintenance ···································· P.27

■

Storage &Troubleshooting ··········· P.33

■

Removing, Disposing of,

and Replacing Parts ······················ P.34

■

Notice of CE Marking ···················· P.35

Summary of Contents for IPC40-E

Page 9: ...9 Dimensions ...