1

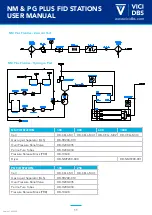

NM & PG PLUS FID STATIONS

USER MANUAL

Version 1.03.0000

www.vicidbs.com

TECH SUPPORT

Europe, Asia, Africa, Australia & New Zealand:

techsupport@vicidbs.com

USA, Canada, Central & South America:

techsupportusa@vicidbs.com

Italy

service@vicidbs.com

VICI AG INTERNATIONAL

Parkstrasse 2

CH-6214 Schenkon

Switzerland

tel: +41 41 925-6200

fax: +41 41 925-6201

web: www.vicidbs.com

APPLICABLE MODELS

This manual is applicable to the following models:

• NM Plus 100 FID Station

• NM Plus 300 FID Station

• NM Plus 600 FID Station

• NM Plus 1000 FID Station

• PG Plus 100 FID Station

• PG Plus 250 FID Station

Version 1.03.0000