MAGNETIC DRIVE PUMPS

SERIES 823 - STEEL

825 - CAST IRON

827 - STAINLESS STEEL

SIZES LQ, LS, Q & QS

VIKING PUMP, INC.

•

A Unit of IDEX Corporation

•

Cedar Falls, IA 50613 USA

SECTION TSM 845.1

PAGE

1 Of 13

ISSUE

C

TECHNICAL SERVICE MANUAL

CONTENTS

WARNING !

Persons with surgical implants of a

metallic or electronic nature should

avoid working on pump – especially the

inner magnet assembly.

MODEL NUMBER CHART

UNMOUNTED PUMP

UNITS

LQ-825, 823, 827

Units are designated by the un-

mounted pump model numbers

followed by the magnetic coupling

size and a letter indicating drive style:

B – Bracket Mount

R – Viking Reducer Drive

P = Commercial Reducer Drive

(Example: LS-827 MD-D140 R)

LS-825, 823, 827

Q-825, 823, 827

QS-825, 823, 827

Introduction . . . . . . . . . . . . . . . . . . . . . . . 1

Special Information . . . . . . . . . . . . . . . . . . . 3

Pressure Relief Valves . . . . . . . . . . . . . . . . . 3

Maintenance . . . . . . . . . . . . . . . . . . . . . . 3

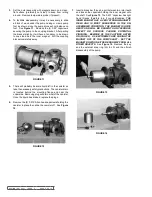

Disassembly: Pump. . . . . . . . . . . . . . . . . . . 6

Pump Rotation . . . . . . . . . . . . . . . . . . . . . 7

Port Arrangement . . . . . . . . . . . . . . . . . . . . 7

Disassembly: MD-D Series Coupling . . . . . . . . . . 7

Bearing Housing . . . . . . . . . . . . . . . . . . . . 9

Disassembly of Bearing Housing . . . . . . . . . . 9

Assembly of Bearing Housing . . . . . . . . . . . . 9

Installation of Bushings . . . . . . . . . . . . . . . . . 9

Pump Assembly. . . . . . . . . . . . . . . . . . . . .10

Adjusting Head Gasket End Clearance . . . . . . . . 11

Assembly: D Series Coupling . . . . . . . . . . . . . 11

Troubleshooting . . . . . . . . . . . . . . . . . . . . 12

Pressure Relief Valves . . . . . . . . . . . . . . . . 12

Pressure Adjustment . . . . . . . . . . . . . . . 12

Disassembly: Relief Valve. . . . . . . . . . . . . 13

Assembly: Relief Valve . . . . . . . . . . . . . . 13

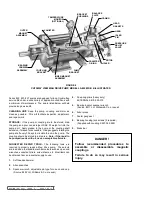

fIGURE 1

LS-825 MD-D290 R

Complete Unit on Base with Viking “C” Reducer

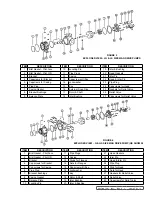

fIGURE 2

QS-825 MD-D450 B

Bearing Carrier, footed Pump and Coupling Bracket

Jacketed Pump Bracket

INTRODUCTION

The illustrations used in this manual are for identification

purposes only and should not be used for ordering parts.

Secure a parts list from the factory or a Viking

®

representative.

Always give the complete name of the part, model and serial

number of the pump when ordering repair parts. The pump

model and serial number can be found on the nameplate

secured to the pump.

In the Viking model number system, the basic size letters are

combined with series number (825, 823, or 827) indicating

basic pump construction material (cast iron, steel or stainless

steel).

This manual deals only with Series 825, 823 and 827 magnetic

drive pumps and couplings.

Refer to figures 1 through

21

for general configurations and nomenclature used in this

manual. Pump specifications and recommendations are listed

in Catalog Section 845.