530 S/SN Operating Manual

m-530sn-gb-02

1

Contents

2 Declaration of incorporation

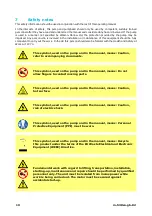

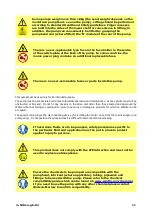

4 Information for returning pumps

5 Peristaltic pumps - an overview

9 Good pump installation practice

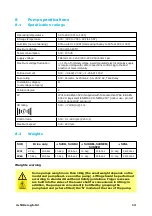

10.1 Keypad Layout and Key IDs

10.5 Change rotation direction

11 Connecting to a power supply

13 Switching the pump on for the first time

13.1 Selecting the display language