SPECIFICATIONS

POWER SUPPLY REQUIREMENTS

120 or 230 V, 60 Hz

MOTOR

Split Phase

HORSEPOWER

1 HP .................... (CWS100)

3/4 HP ................ (CWS75)

1/2 HP...................(CWS50)

LIQUID TEMPERATURE RANGE

40° F- 120° F

CUT IN PRESSURE

30 PSI

CUT OUT PRESSURE

50 PSI

640000-001 B 08/18

© 2018, WAYNE/Scott Fetzer Company.

CONSTRUCTION

MOTOR HOUSE

Cast Iron

SEAL PLATE

Cast Iron

DIFFUSER

Thermoplastic

IMPELLER

Thermoplastic

SHAFT

Carbon Steel

PUMP SUCTION

1-1/4 in. NPT

PUMP DISCHARGE

3/4 in. NPT

Convertible Well Jet Pump Water Systems

www.waynepumps.com

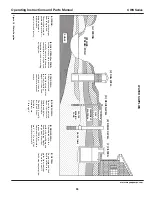

PERFORMANCE

Model

HP PSI 0 ft

10 ft 20 ft 30 ft 40 ft 50 ft 60 ft 70 ft 80ft 90 ft

CWS100

1

30

1056

948

846

750

642

516

384

294

234

180

40

840

750

642

528

384

294

234

180

126

72

50

588

444

330

264

234

180

126

72

-

-

CWS75

3/4

30

990

906

774

630

510

408

306

246

186

54

40

780

630

510

408

306

246

186

114

54

-

50

462

330

270

216

156

90

-

-

-

-

CWS50

1/2

30

900

780

690

570

456

348

270

180

90

-

40

660

570

450

348

270

180

90

-

-

-

50

408

300

210

150

60

-

-

-

-

-

Intended for Indoor Use Only

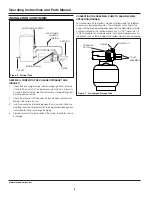

Please read and save these instructions. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property

damage! Retain instructions for future reference.

Operating Instructions and Parts Manual

CWS Series

* Refer to Page 13 for Jet Assembly Part Numbers