Summary of Contents for FCF 10

Page 2: ......

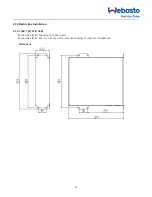

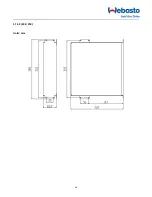

Page 16: ...16 4 13 2 20K 25K Units mm ...

Page 19: ...19 WIRING DIAGRAM 12K 115V 12K 230V The specification of power cord is AWG12 3 3 2 5 ...

Page 20: ...20 WIRING DIAGRAM 16K 115V 16K 230V The specification of power cord is AWG12 3 3 2 5 ...

Page 30: ...30 NOTES ...

Page 31: ...31 NOTES ...