WARNING: This product, when used for soldering and similar applications, produces chemicals known to the State of

California to cause cancer and birth defects or other reproductive harm

.

1

MODEL WES51 ELECTRONIC SOLDERING STATION

DESCRIPTION

The WES51 Soldering Station is one in a series of products, which have been developed for industrial manufacturing as

well as for the rework and repair sector. The microprocessor control allows for simple and easy operation. The digital

electronic control system offers excellent control performance for various soldering jobs.

A grounded soldering iron tip, zero power switching and anti-static design of the station and tool allows the WES51

Soldering System to meet the high quality standards established by Weller

®

. The station features external tip temperature

offset and the ability to lock the tip temperature setting using the PW50 Probe supplied. The station will automatically

enter a sleep mode and shut off power to the tool and indicator LED after 99 minutes of inactivity.

Tip temperature is adjustable in the range of 350°F to 850°F (177°C to 454°C), with the front panel temperature control

knob. The LED power indicator will be Green for normal operation or Red, if the temperature is Locked. The LED for

the WES51 will also indicate the operation of the station by the following sequence: Indicator LED full On, indicates that

the station is ramping up to temperature (this can be indicated in either the Green Unlocked mode or the Red

Locked mode). Indicator LED full Off or flashing steadily, indicates that the station has reached the Set Point (this also

can be indicated in either the Green Unlocked mode or the Red Locked mode). This soldering station is UL/CUL

listed and meets all applicable standards for the CE mark.

OPERATING INSTRUCTIONS

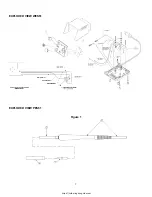

Unpack unit carefully. Place spring and funnel in slot in top of tool stand. Dampen the sponge, distilled or de-ionized water

is preferred. Insert tool in holder and connect tool plug to receptacle on power unit; rotate plug housing Clockwise (CW) to

lock plug into receptacle. Insert line cord plug into properly grounded AC receptacle and turn station On. Set

temperature control knob to desired tip temperature. Wait 30 seconds. Remove tool from holder and tin tip with solder. Unit

is ready for use once the LED begins to flash, indicating that it has reached the operating temperature (indicated in either

the Green or Red mode).

Always use the lowest temperature that will handle the load that you are soldering. The Weller

®

electronic control provides

maximum power to the heated load even when set to the lowest temperature; therefore, there is no need to use high

temperatures to handle heavy soldering loads. By using lower temperatures and properly selecting tip styles, sensitive

components will be protected from heat damage.

WARNING:

Do not remove ground prong from line cord plug. Removal may cause tip temperature control to be erratic.

AVAILABLE MODELS AND HAND PIECES

PRODUCT

DESCRIPTION

WES51

Power unit, 120V 60Hz, °F dial markings, PES51 tool and tool stand

WES51DUK

Power unit, 230V 50/60 Hz, °C dial markings, PES51 tool and tool stand

PES51

50 watt Soldering Tool w/ETA Tip