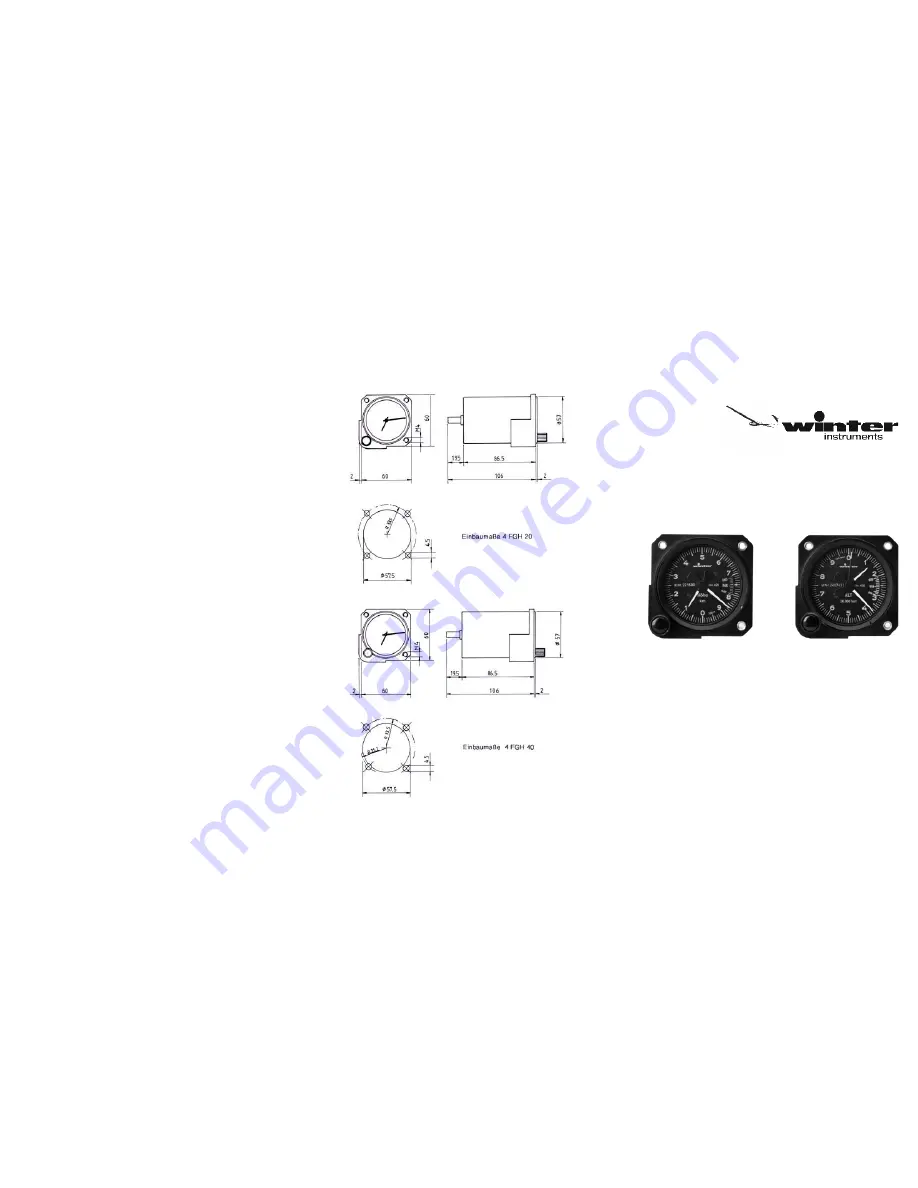

mounting dimensions:

mounting dimensions:

LBA-Anerkennung:

Herstellungsbetrieb gemäß EASA Ref. DE.21G.0115 Instandhaltungsbetrieb gemäß EASA Ref. DE.145.0305

EINBAU- UND WARTUNGSANWEISUNG FÜR DIE HÖHENMESSER

4 FGH 20 und 4 FGH 40

Ausgabe: September 2014

INSTALLATION AND MAINTENANCE INSTRUCTIONS FOR ALTIMETERS

4 FGH 20 and 4 FGH 40

Issue: September 2014

Gebr. Winter GmbH & Co. KG

Hauptstraße 25 · D-72417 Jungingen

T49 (0) 74 77 2 62 + 15 12 63

T49 (0) 74 77 10 31

e-mail: info@winter-instruments.de

Internet: www.winter-instruments.de

4 FGH 20 S Nr. 4220

4 FGH 40, S Nr. 4550

INSTALLATION INSTRUCTIONS

The mounting dimensions of the altimeter correspond to the so-called small standard. The

diameter of the hole in the instrument panel is 57 mm, the hole circle diameter on the mounting

flange is 67 mm. M 4 countersunk screws are used for fastening. The instrument panel should be

flat and fixing holes should be accurately located for stressfree mounting of the instrument. The

instrument panel should be well sprung.

The altimeter must be connected to the static pressure. Static pressure is tapped either from the

second connection of the pitot tube or by static pressure sensor attached to the fuselage sides.

The pressure tapping point should be selected so that no errors are produced from air flow around

the aircraft fuselage.

Hose leads should be as short as possible and must not be twisted or contain sharp bends.

Kinking of hoses should be avoided in all cases. Hoses and connections must be absolutely leak-

tight. The instruments must be protected from water penetration. If the hoses from the pressure

tapping points cannot be run upwards, a water trap (waterbag) should be fitted at the lowest point.

Before putting into service, a test must be carried out for leak-tightness. If the aircraft manufacturer

has not given any special instructions for this, our standard instruction for leak-tightness testing,

January 1978 edition, can be used.

MAINTENANCE INSTRUCTIONS

Leak testing should be carried out at least every 2 years. Otherwise, the instrument does not

require any maintenance.

RETESTING AND REPAIR

The service condition and accuracy of measurement of the altimeter is normally retained over a

long period. For obvious malfunction the unit should be subjected to an investigation at the

manufacturer or a suitable aircraft engineering company. It should be packed to protect it from

impacts, and the connections should be sealed. Under no circumstances should you interfere with

the measuring mechanism of the altimeter. We recommend that altimeters are subjected to

periodic retesting after 5 years.

1) Test certificate EASA FORM ONE

2) Installation and maintenance instructions

1) Test certificate EASA FORM ONE

ACCOMPANYING DOCUMENT:

New instrument:

Used instrument:

ATTENTION

This issue replace all previous editions.