Workrite Ergonomics | 800.959.9675 www.workriteergo.com

1 of 12

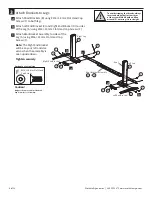

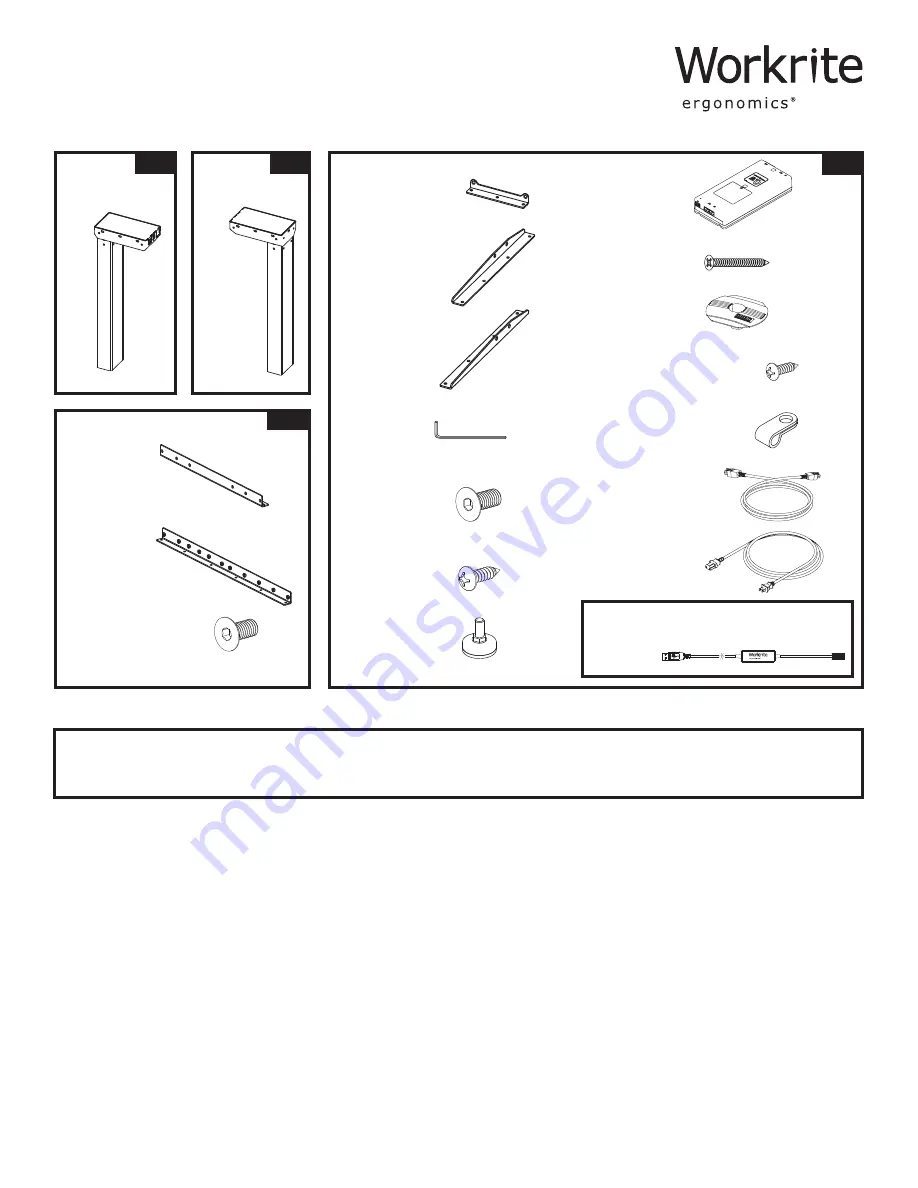

Box 1

Box 2

Box 4

Box 3

Parts Included

Required & Sold Separately

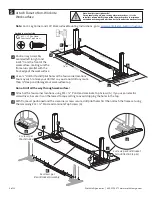

Q

Rear Bracket

Qty: 2

R

Connector Bracket

Qty: 1

A

Leg

Qty: 1

A

Leg

Qty: 1

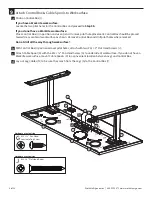

S

#M6 × 12 mm Flat

Head Cap Screw

Qty: 8

Assembly & Installation Instructions:

Sierra 2-Leg Workcenter SEHX54–72*, SEHXL54-72

Styled or Flat Foot Kit

Standard or Programmable Switch

Worksurface

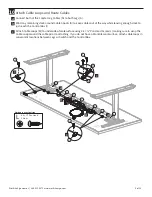

E

4 mm Allen Wrench

Qty: 1

N

Leg Cable, 1

meter

Qty: 2

O

Power Cord

Qty: 1

K

Cable Spool

Qty: 2

M

3/16" Cable Loops

Qty: 10

B

Short Bracket

Qty: 2

I

Control Box

Qty: 1

H

Foot Glide

Qty: 4

C

Left End Bracket

Qty: 1

D

Right End Bracket

Qty: 1

F

#M6 × 14 mm Flat Head Cap

Screw

Qty: 20

L

#8 × ⅝" Pan Head Screw

Qty: 12

G

#12 × ¾" Pan Head Laminate

Top Screw

Qty: 38

J

#12 × 2" Flat Head Screw

Qty: 2

P

*Sierra Interface Kit Cable included

with HX models

Qty: 1